Paper cup machines are essential pieces of equipment in the manufacturing industry, producing disposable cups for various applications. Proper maintenance and care of these machines not only enhance their longevity but also ensure consistent production quality. This guide will provide you with comprehensive tips and practices for maintaining your paper cup machine, ensuring it operates efficiently and reliably.

Understanding the Components

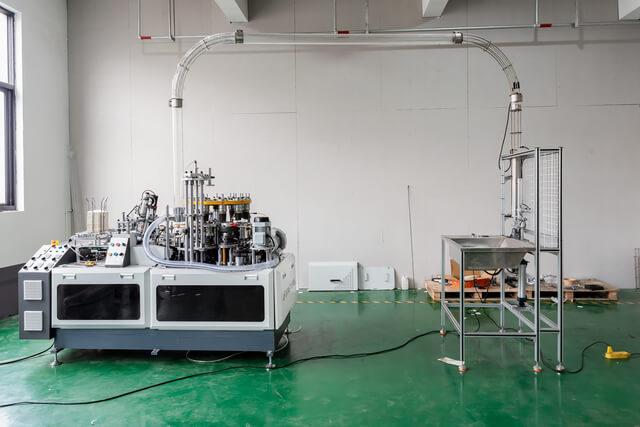

Before diving into maintenance practices, it’s important to understand the key components of a paper cup machine. These machines typically consist of a feeder, forming station, heating and sealing units, and a stacking section. Each part plays a critical role in the overall functionality. Familiarizing yourself with these components will help identify areas that require regular attention.

Regular Cleaning Protocols

One of the most crucial aspects of machine maintenance is regular cleaning. Dust and residue can accumulate and affect the performance of the machine. It is recommended to clean the machine daily at the end of production shifts. Use a soft cloth and appropriate cleaning agents to wipe down surfaces. Pay special attention to areas where paper fibers may build up, as this can lead to jams and inefficiencies.

Lubrication of Moving Parts

Proper lubrication of moving parts is essential for reducing friction and wear. Check the machine’s manual for specific lubrication points and recommended lubricants. Typically, oil should be applied to bearings, gears, and other moving components at least once a week. This practice will not only prolong the lifespan of the machine but also ensure smoother operation.

Inspection of Electrical Components

Electrical components are vital for the functionality of a paper cup machine. Regularly inspect wires, connectors, and control panels for any signs of wear or damage. Look for frayed wires or loose connections that could cause electrical failures. Additionally, ensure that all safety features are operational to prevent accidents during production.

Monitoring Temperature Settings

The temperature settings in the heating and sealing units of the machine are crucial for the quality of the final product. It’s important to regularly monitor and calibrate the temperature controls to ensure they are set according to the material specifications. Inconsistent temperatures can lead to poorly sealed cups, resulting in product wastage and increased costs.

Checking for Wear and Tear

Like any machinery, paper cup machines undergo wear and tear over time. Regularly inspect all mechanical parts for signs of deterioration. This includes checking the forming molds, rollers, and cutting blades. If any component appears worn, it should be replaced immediately to avoid further damage and maintain production efficiency.

Software Updates and Calibration

If your paper cup machine is equipped with digital controls or software, keeping the system updated is essential. Manufacturers often release updates that improve functionality and fix bugs. Additionally, calibrating the machine according to the specific requirements of your production line will help maintain optimal performance and product quality.

Training Personnel on Proper Usage

Even the best-maintained machines can fail if operators are not properly trained. Ensure that all personnel involved in operating the paper cup machine are adequately trained on its functions and maintenance protocols. Regular workshops and training sessions can help reinforce best practices and keep everyone informed about any changes in procedures or machinery.

Keeping Spare Parts Handy

Having a stock of essential spare parts can significantly reduce downtime in case of unexpected failures. Identify the most commonly replaced parts for your specific machine model and keep them readily available. This proactive approach allows for quick repairs and ensures that production remains uninterrupted.

Documenting Maintenance Activities

Keeping a detailed log of all maintenance activities performed on the paper cup machine is beneficial for tracking its health and performance over time. Record dates of inspections, cleaning, lubrication, and any parts replaced. This documentation not only helps in identifying recurring issues but also aids in future troubleshooting.

Conclusion: Ensuring Longevity and Efficiency

Maintaining a paper cup machine is an ongoing process that requires diligence and attention to detail. By implementing a comprehensive maintenance plan that includes regular cleaning, lubrication, inspection, and operator training, you can ensure the machine operates at peak efficiency. Taking these steps will ultimately save time and resources, enhance product quality, and extend the lifespan of your equipment. Remember, a well-maintained machine is the backbone of a successful production operation.

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China