paper cup machine fully automatic play a crucial role in the food industry, particularly in the production of disposable cups used for beverages and other consumables. As the demand for environmentally friendly packaging increases, these machines have evolved to meet various industry needs while focusing on efficiency, quality, and sustainability. This article explores the key characteristics of paper cup machine fully automatic used in the food industry, highlighting their importance and functionality.

High Production Capacity

One of the standout features of paper cup machine fully automatic is their ability to achieve high production capacity. These machines are designed to operate at rapid speeds, producing thousands of cups per hour. This efficiency is essential for manufacturers aiming to meet the growing demand from cafes, restaurants, and vending services. High production capacity not only ensures a steady supply of products but also reduces per-unit production costs, making it an attractive option for businesses looking to scale their operations.

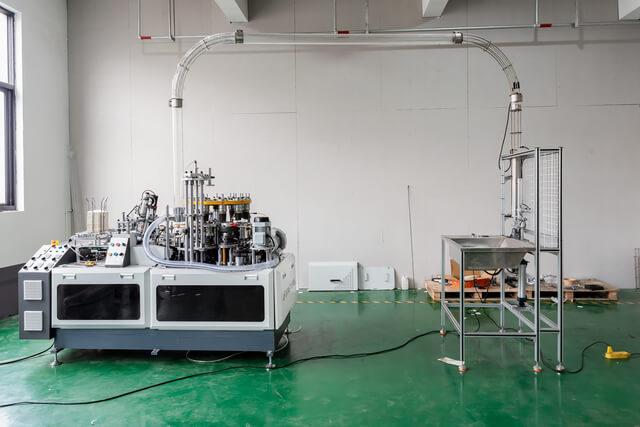

Advanced Automation

Modern paper cup machine fully automatic incorporate advanced automation technologies that streamline the manufacturing process. Automated systems minimize human intervention, reducing the risk of errors and enhancing overall operational efficiency. Features such as automatic feeding, cutting, and stacking allow for continuous production without significant downtime. Moreover, automation contributes to consistent product quality, as machines can maintain precise control over various parameters throughout the manufacturing process.

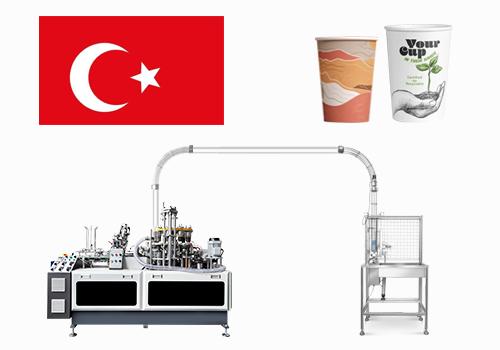

Versatility in Cup Design

Another critical characteristic of paper cup machine fully automatic is their versatility in producing different cup designs and sizes. These machines can be configured to manufacture a wide range of cup types, including hot cups, cold cups, and specialty cups for specific beverages. This adaptability makes them ideal for businesses that require customized solutions to cater to various customer preferences. Additionally, many machines allow for the incorporation of branding elements, enabling companies to create unique and recognizable packaging.

Eco-Friendly Manufacturing

As sustainability becomes increasingly important in the food industry, paper cup machines are designed with eco-friendly manufacturing processes in mind. Many machines utilize biodegradable or recyclable materials, contributing to reduced environmental impact. Additionally, advancements in technology have led to the development of machines that minimize waste during production. This focus on sustainability not only appeals to environmentally conscious consumers but also helps companies comply with regulations regarding packaging waste.

User-Friendly Operation

User-friendliness is another characteristic that distinguishes modern paper cup machine fully automatic. Manufacturers are incorporating intuitive interfaces and easy-to-navigate controls, allowing operators to quickly learn how to use the equipment. This simplicity reduces training time and enhances overall productivity. Furthermore, many machines come equipped with diagnostic features that alert users to potential issues, facilitating prompt maintenance and minimizing downtime.

Quality Control Systems

Ensuring product quality is paramount in the food industry, and paper cup machines are equipped with sophisticated quality control systems. These systems monitor various aspects of the production process, including material thickness, cup dimensions, and sealing integrity. By implementing automated quality checks, manufacturers can identify defects early in the production line, thereby reducing waste and ensuring that only high-quality products reach the market. This focus on quality helps businesses maintain their reputation and customer satisfaction.

Energy Efficiency

The energy consumption of manufacturing equipment is a significant consideration for businesses striving for cost-effectiveness. Many modern paper cup machine fully automatic are designed with energy efficiency in mind, utilizing advanced technologies to reduce power consumption without compromising performance. Energy-efficient machines can lead to substantial cost savings over time, allowing companies to allocate resources more effectively and contribute to sustainable practices within the industry.

Reliability and Durability

Reliability and durability are essential characteristics of paper cup machine fully automatic, as they undergo continuous operation in demanding environments. High-quality materials and robust engineering ensure that these machines can withstand the rigors of daily use. Manufacturers often provide warranties and support services to reassure customers of their machines' longevity. Investing in reliable equipment reduces the likelihood of breakdowns and maintenance costs, further enhancing overall business efficiency.

Conclusion

In conclusion, paper cup machine fully automatic are vital assets in the food industry, characterized by their high production capacity, advanced automation, and versatility in design. Their eco-friendly manufacturing processes and user-friendly operation make them essential for businesses seeking sustainability and efficiency. Additionally, robust quality control systems, energy efficiency, and reliability further enhance their value. As the demand for disposable products continues to grow, investing in state-of-the-art paper cup machines is crucial for companies aiming to remain competitive while meeting consumer expectations for quality and sustainability.

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China