Choosing the right best paper cup manufacturing machine is crucial for businesses looking to enter or expand in the paper cup manufacturing industry. With a variety of machines available, each designed for specific outputs and purposes, making the right choice can significantly impact production efficiency, product quality, and ultimately, profitability. In this article, we will explore key considerations for selecting a paper cup machine that best suits your business needs.

Understand Your Production Requirements

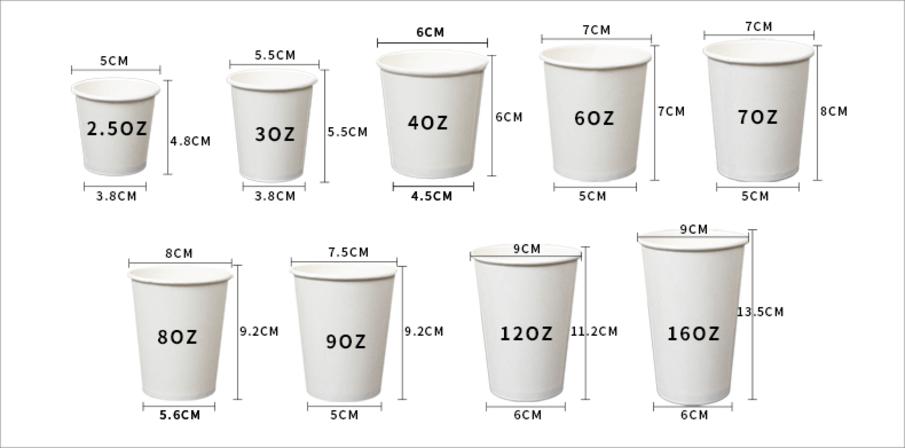

The first step in choosing a best paper cup manufacturing machine is to clearly define your production requirements. Consider the volume of cups you need to produce daily or monthly. For high-volume production, opt for machines with advanced automation features that can operate at higher speeds. Conversely, if your business is just starting out or operates on a smaller scale, a semi-automatic machine may suffice. Additionally, think about the types of cups you want to manufacture—whether they are hot or cold beverage cups, and the sizes you need to accommodate.

Evaluate Machine Features

Different best paper cup manufacturing machine come equipped with various features that can enhance production quality and efficiency. Look for machines that offer adjustable parameters, such as cup size and thickness. Features like automatic feeding, cutting, and stacking mechanisms can save time and reduce labor costs. Some advanced models also include quality control systems that can detect defects during production, ensuring consistent product quality. Assessing these features against your production goals will help streamline your operations.

Consider Material Compatibility

Another critical factor is the type of paper materials the machine can handle. Different paper grades will affect not only the quality of the cups produced but also the machine's performance. Ensure that the machine you select is compatible with the types of paper you intend to use, whether it’s single-layer, double-layer, or coated paper. The ability to work with biodegradable or recyclable materials can also be a significant advantage, aligning your business with sustainability trends and consumer preferences.

Assess Space and Layout Constraints

Your production facility's layout and available space play a vital role in your machine selection. Larger machines often require more floor space and may have specific installation requirements, including power supply and ventilation. It’s essential to plan the layout in advance, considering not only the machine itself but also the workflow around it, including raw material storage, finished goods storage, and any necessary packing areas. A well-planned layout can enhance operational efficiency.

Evaluate Supplier Reputation and Support

The reputation of the machine supplier is a significant consideration. Research potential suppliers and read reviews from other businesses that have purchased similar machines. It's important to choose a supplier known for providing high-quality machinery and excellent after-sales support. Reliable customer service can make a huge difference, especially when troubleshooting issues or requiring maintenance. Look for suppliers that offer comprehensive warranties, training, and ongoing technical support.

Analyze Cost and Budget

Cost is always a determining factor in any business investment. When selecting a best paper cup manufacturing machine, consider both the initial purchase price and the ongoing operational costs. While it might be tempting to choose the cheapest option, remember that lower-priced machines may not offer the same reliability and efficiency as higher-end models. Factor in the cost of maintenance, spare parts, and potential upgrades when budgeting. A more expensive machine that performs better and lasts longer can ultimately save money in the long run.

Explore Technological Advancements

In today's rapidly evolving market, technology plays a pivotal role in manufacturing processes. Look for machines that incorporate the latest technological advancements, such as automation, smart sensors, and connectivity options. These technologies can enhance efficiency, reduce waste, and improve overall production quality. Investing in a machine with advanced technology can also position your business for future growth and adaptability in changing market conditions.

Conduct a Trial Run

Before committing to a purchase, if possible, conduct a trial run with the machine. Many reputable suppliers offer demonstrations or allow potential buyers to test the equipment. This hands-on experience can provide invaluable insights into how the machine operates and how well it meets your production needs. Pay attention to factors such as ease of operation, maintenance requirements, and the quality of the cups produced during the trial.

Stay Informed About Industry Trends

The best paper cup manufacturing machine industry is continuously evolving due to changes in consumer preferences, environmental regulations, and technological advancements. Stay informed about industry trends and innovations that could impact your business. Engaging with industry associations, attending trade shows, and networking with other professionals can provide valuable insights and help you make informed decisions about your machinery and overall business strategy.

Conclusion

Choosing the right best paper cup manufacturing machine is a critical decision that requires careful consideration of various factors, including production requirements, machine features, material compatibility, and budget constraints. By taking the time to thoroughly assess these elements and engaging with reputable suppliers, you can find a machine that not only meets your current needs but also supports your business's growth and adaptability in the future. Making an informed choice will help you establish a successful and efficient paper cup manufacturing operation.

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China