The food packaging industry has seen significant advancements in technology, with the application of paper cup machines becoming a vital component. These machines are designed to produce high-quality paper cups efficiently, catering to the growing demand for sustainable and eco-friendly packaging solutions. This article explores the various aspects of paper cup machines, their benefits, and their impact on the food packaging industry.

Overview of Paper Cup Machines

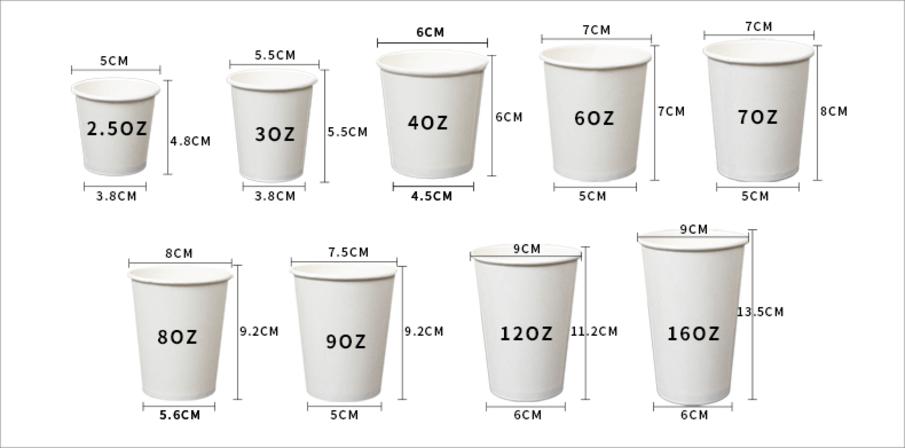

Paper cup machines are automated systems that manufacture paper cups from rolls of paper. These machines can produce a variety of cup sizes and styles, including hot drink cups, cold drink cups, and specialty cups for desserts. The production process typically involves forming, printing, cutting, and sealing the cups, ensuring a high level of precision and consistency. As the need for disposable packaging increases, these machines have become essential for many businesses in the food sector.

Sustainability and Environmental Impact

One of the most significant advantages of using paper cups is their environmental friendliness compared to plastic options. Paper cup machines enable companies to produce biodegradable and recyclable cups, aligning with global efforts to reduce plastic waste. Many manufacturers are now focusing on sourcing sustainable materials and implementing eco-friendly practices in their production processes. By investing in paper cup machines, companies not only comply with environmental regulations but also meet consumer demand for greener alternatives.

Technological Advancements in Paper Cup Manufacturing

Recent advancements in technology have greatly improved the efficiency and capabilities of paper cup machines. Modern machines are equipped with features such as automatic feeding systems, high-speed production capabilities, and advanced quality control mechanisms. These innovations allow manufacturers to increase output while maintaining high standards of quality. Moreover, the integration of digital technology and automation has streamlined the production process, reducing labor costs and minimizing human error.

Diverse Applications in the Food Packaging Sector

Paper cups produced by these machines are utilized across various segments of the food packaging industry. From coffee shops and restaurants to food delivery services, paper cups serve as a versatile packaging solution for both hot and cold beverages. Additionally, specialized paper cups designed for specific products, such as ice cream or desserts, have gained popularity. This versatility makes paper cup machines a valuable investment for businesses looking to diversify their product offerings.

Cost Efficiency and Production Scalability

The cost efficiency of paper cup machines plays a crucial role in their adoption within the food packaging industry. While the initial investment may be significant, the long-term savings on materials and labor often justify the expenditure. Additionally, these machines can be scaled to meet varying production demands, allowing businesses to adjust their output based on market trends. This flexibility is particularly beneficial for companies experiencing fluctuating demand, as they can quickly adapt their production levels without incurring excessive costs.

Challenges and Considerations

Despite the numerous benefits, the implementation of paper cup machines is not without challenges. One significant issue is the availability and cost of quality raw materials. As demand for sustainable paper products rises, securing reliable sources of high-quality paper can become more competitive and costly. Furthermore, manufacturers must navigate regulatory compliance regarding food safety and environmental standards, which can complicate the production process. Businesses must carefully assess these factors when considering investment in paper cup technology.

Future Trends in Paper Cup Technology

The future of paper cup manufacturing looks promising, with ongoing innovations expected to enhance production processes further. Emerging trends include the development of more advanced materials that improve the durability and insulation of paper cups. Additionally, manufacturers are exploring opportunities for customization, allowing brands to create unique designs that enhance their visibility in a crowded market. The shift towards circular economy practices will also likely influence the evolution of paper cup machines, promoting recycling and reusability within the industry.

Conclusion

In conclusion, the application of paper cup machines in the food packaging industry represents a significant advancement towards sustainable and efficient practices. These machines not only cater to the growing demand for eco-friendly packaging solutions but also provide manufacturers with the ability to produce high-quality products at scale. As technology continues to evolve, the potential for further innovations in this field remains vast. Companies that embrace these advancements will likely find themselves well-positioned to thrive in an increasingly environmentally conscious marketplace.

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China