The production of paper cups has gained significant popularity due to the increasing demand for eco-friendly and disposable dining options. This trend has led to the development of advanced paper cup machines that require careful selection and influence of raw materials. The choice of materials not only affects the quality and durability of the cups but also plays a crucial role in sustainability and cost-effectiveness. In this article, we will explore the various aspects of selecting raw materials for paper cup machine production, including the types of materials available, their properties, and the factors influencing these choices.

Types of Raw Materials

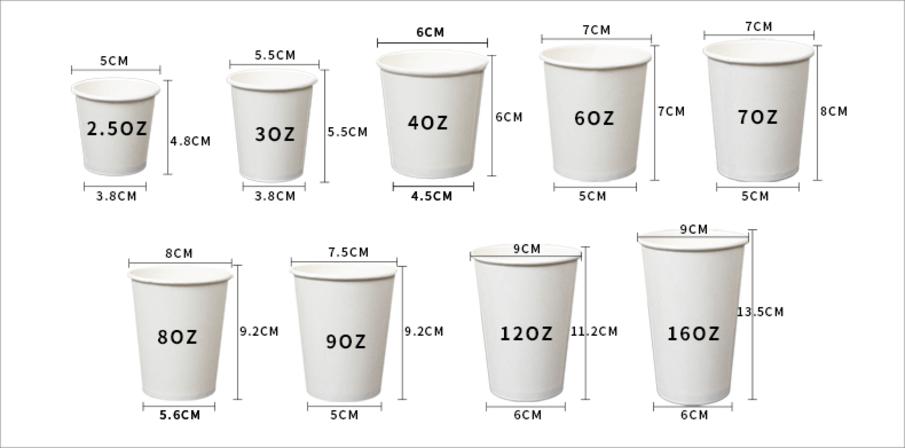

The primary raw materials used in the production of paper cups include paperboard, coatings, and additives. The most commonly used paperboard is made from virgin pulp or recycled fibers. Virgin pulp offers superior strength and printability, while recycled fibers contribute to environmental sustainability. Coatings, typically made from polyethylene (PE) or biodegradable alternatives, provide moisture resistance, ensuring that the cups can hold liquids without leaking. Additives may include fillers, dyes, and other substances that enhance the performance and appearance of the cups.

Properties of Raw Materials

When selecting raw materials for paper cup production, it is essential to consider their physical and chemical properties. The thickness, weight, and grammage of paperboard are critical factors that influence the cup's structural integrity. A thicker board can withstand higher temperatures and pressures, making it suitable for hot beverages. Additionally, the coating material must ensure that the cups remain waterproof while being compatible with recycling processes. Understanding these properties allows manufacturers to optimize their production processes and meet customer expectations.

Sustainability Considerations

Sustainability is a growing concern in the paper cup industry. Manufacturers are increasingly turning to eco-friendly materials, such as biodegradable coatings and recycled paperboard. The use of sustainable materials not only reduces the environmental impact but also appeals to a more environmentally conscious consumer base. Moreover, certifications such as FSC (Forest Stewardship Council) and SFI (Sustainable Forestry Initiative) provide assurance that the raw materials are sourced responsibly. Companies that prioritize sustainability often find themselves gaining a competitive edge in the market.

Cost-Effectiveness

The cost of raw materials significantly influences the overall production costs of paper cups. Manufacturers must balance the quality of materials with their prices to maintain profitability. While high-quality virgin pulp may produce superior cups, the associated costs can be prohibitive. Conversely, using lower-quality recycled materials may reduce costs but could compromise the final product's integrity. It is crucial for manufacturers to conduct a thorough cost-analysis to determine the most viable raw material options without sacrificing quality.

Supplier Relationships

The choice of suppliers plays a vital role in the raw materials selection process. Establishing strong relationships with reliable suppliers ensures a consistent supply of quality materials. Manufacturers should assess suppliers based on their ability to provide certified materials, adhere to delivery schedules, and maintain competitive pricing. Developing long-term partnerships can also lead to better negotiation terms and access to innovative materials that enhance product offerings.

Regulatory Compliance

Manufacturers must stay informed about regulations governing the materials used in food contact products. Compliance with food safety standards is essential to ensure that the raw materials do not pose health risks to consumers. Regulations may vary by region, so it is important for manufacturers to understand the specific requirements applicable to their market. Working with suppliers who provide compliant materials can help streamline the certification process and reduce potential liabilities.

Innovation and Trends

The paper cup industry is witnessing rapid innovations aimed at improving functionality and sustainability. New materials, such as compostable bioplastics and plant-based coatings, are being developed to replace traditional plastic linings. These innovations not only improve the environmental footprint of paper cups but also open up new market opportunities. Manufacturers should keep abreast of industry trends and be willing to adapt their raw material choices to incorporate the latest advancements.

Conclusion

In conclusion, the selection and influence of raw materials for paper cup machine production are multifaceted processes that require careful consideration. From the types of materials used to their properties and sustainability aspects, each factor plays a crucial role in determining the quality and marketability of the final product. Manufacturers must navigate the complexities of cost, supplier relations, and regulatory compliance to create effective production strategies. By staying informed about industry innovations and trends, companies can ensure their products remain competitive and aligned with consumer demands for sustainability and quality.

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China