In today's rapidly evolving market, the customization of paper cup machines plays a crucial role in meeting diverse consumer demands. Businesses are increasingly seeking ways to adapt their production capabilities to cater to specific market trends, preferences, and environmental considerations. This article explores essential strategies for customizing paper cup machines to enhance operational efficiency and align with customer expectations.

Understanding Market Demand

The first step in customizing a paper cup machine is to thoroughly understand the current market demand. This involves analyzing consumer preferences, competitor offerings, and emerging trends. For instance, there has been a noticeable shift towards eco-friendly products, prompting manufacturers to consider biodegradable materials. Conducting market research through surveys, focus groups, and sales data will provide valuable insights into what consumers desire. This foundational knowledge will guide manufacturers in making informed decisions regarding the features and specifications of their machines.

Identifying Key Customization Features

Once market demand is understood, the next step is identifying key features that can be customized on paper cup machines. This may include adjustments in size, shape, and printing capabilities. For example, if there is a rising trend for larger beverage containers, machines may need the capability to produce bigger cups. Additionally, incorporating advanced printing technology allows businesses to offer personalized designs, which can make their products more appealing. Customization options such as cup thickness and insulation properties should also be considered based on consumer feedback.

Integrating Eco-Friendly Practices

As sustainability becomes a significant concern among consumers, integrating eco-friendly practices into the customization of paper cup machines is essential. This includes using recyclable or compostable materials and reducing waste during the production process. Manufacturers can customize machines to handle alternative materials, such as plant-based plastics or recycled paper. Further, implementing energy-efficient technologies in the manufacturing process can appeal to environmentally conscious consumers and reduce operational costs in the long run.

Enhancing Production Speed and Efficiency

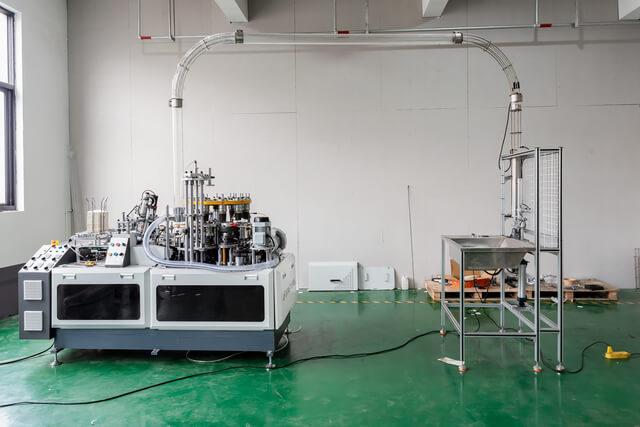

Customization should also focus on improving production speed and efficiency. In a competitive market, being able to produce high volumes of paper cups quickly can provide a significant advantage. Manufacturers can modify their machines to increase output capacity while maintaining quality. Introducing automation through smart technology can streamline operations, allowing for real-time monitoring and adjustments during production. This not only reduces labor costs but also minimizes human error, ensuring consistent product quality.

Incorporating Technological Advancements

Technological advancements play a vital role in the customization of paper cup machines. By integrating cutting-edge technologies like artificial intelligence and IoT (Internet of Things), manufacturers can create smarter machines that optimize production processes. These technologies can enable predictive maintenance, reducing downtime and increasing the overall efficiency of the machinery. Additionally, enhanced software solutions can allow for better design flexibility, enabling quicker adjustments to meet changing consumer demands.

Customization for Specific Markets

Different markets may have unique requirements for paper cups, necessitating tailored machine specifications. For example, cafes and restaurants might require cups that can withstand higher temperatures for hot beverages, while events might need disposable cups with elaborate designs. Understanding these specific needs allows manufacturers to customize their machines accordingly, ensuring they can produce suitable products for various market segments. Collaborating with customers to gather feedback on their specific needs can further refine customization efforts.

Testing and Quality Control

After customizing paper cup machines, rigorous testing and quality control measures must be implemented. This ensures that the customized features function properly and meet industry standards. Conducting trials with different materials and designs can help identify potential issues before mass production begins. Establishing quality control protocols will ensure that every cup produced meets the desired specifications, ultimately enhancing customer satisfaction and brand reputation.

Marketing Customized Products

Once the customization process is complete, effective marketing strategies are essential to promote the new capabilities. Highlighting unique features, such as eco-friendliness or innovative designs, can attract consumers who prioritize these attributes. Utilizing social media, influencer partnerships, and targeted advertising campaigns can help reach a broader audience. Additionally, showcasing customer testimonials and success stories can build credibility and encourage potential buyers to consider customized paper cups.

Conclusion: Embracing Customization for Success

In conclusion, customizing paper cup machines according to market demand is a multifaceted process that requires careful consideration of various factors, including consumer preferences, technological advancements, and sustainability. By understanding market trends, identifying key features, and implementing effective manufacturing practices, businesses can position themselves competitively. Embracing customization not only enhances production capabilities but also fosters customer loyalty and satisfaction, leading to long-term success in the dynamic paper cup industry.

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China