The paper cup machine is an essential piece of equipment in the food and beverage industry, enabling businesses to produce disposable cups efficiently. Regular maintenance is vital to ensure the machine operates optimally, extends its lifespan, and minimizes downtime. This guide will provide a comprehensive overview of daily maintenance and general upkeep for paper cup machine equipment, helping operators maintain efficiency and quality in their production processes.

Understanding Your Paper Cup Machine

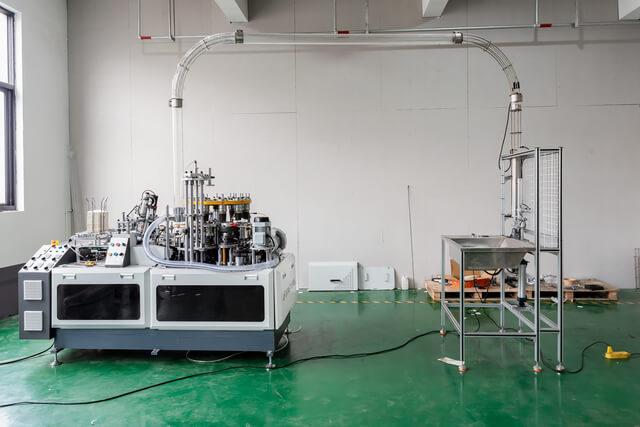

Before delving into maintenance practices, it's crucial to understand the components of your paper cup machine. Typically, these machines consist of several key parts, including the feeder, forming station, sealing section, and cutting unit. Familiarizing yourself with each component allows operators to identify problem areas quickly and perform targeted maintenance effectively.

Daily Maintenance Checklist

To keep your paper cup machine running smoothly, a daily maintenance checklist should be established. This checklist includes inspecting various components, cleaning the machine, and ensuring that all safety measures are adhered to. Key tasks include:

-

Inspecting the feeder for jams or blockages.

-

Checking the forming station for proper alignment and functionality.

-

Cleaning the cutting unit to prevent paper debris buildup.

-

Reviewing the sealing section for any leaks or malfunctions.

By performing these checks daily, operators can catch potential issues early, reducing the likelihood of more severe problems down the line.

Cleaning Procedures

Regular cleaning is essential for maintaining the performance of your paper cup machine. A clean machine not only improves product quality but also enhances safety and efficiency. Operators should focus on the following cleaning procedures:

-

Use compressed air to blow away dust and paper particles from all parts of the machine.

-

Wipe down surfaces with non-abrasive cleaners to prevent corrosion.

-

Pay special attention to the sealing area, as residue can affect the integrity of the cups.

Establishing a routine cleaning schedule helps keep the machine in top condition and prolongs its operational life.

Lubrication of Moving Parts

Proper lubrication of the moving parts in a paper cup machine is crucial to reduce friction and wear. Operators should regularly check the lubrication levels and apply appropriate oils or greases as needed. Key areas to lubricate include:

-

Bearings and shafts to ensure smooth operation.

-

Chains and gears to minimize wear and tear.

-

Any other moving components as specified in the manufacturer's guidelines.

By maintaining proper lubrication, operators can significantly reduce the risk of mechanical failure and enhance machine performance.

Monitoring Electrical Components

Electrical components play a vital role in the operation of paper cup machines, and regular monitoring is essential. Operators should conduct the following checks:

-

Inspect electrical connections for signs of wear or damage.

-

Test emergency stop buttons and safety interlocks to ensure they function correctly.

-

Check the control panel for any error messages or abnormal readings.

Being proactive about electrical maintenance can prevent unexpected shutdowns and enhance overall safety in the production environment.

Troubleshooting Common Issues

Even with diligent maintenance, issues can still arise. It's essential to know how to troubleshoot common problems associated with paper cup machines. Some frequent issues include:

-

Paper jams: Ensure that the feeder is clear and properly aligned.

-

Sealing problems: Check for proper temperature and pressure settings.

-

Quality inconsistencies: Inspect the paper quality and adjust machine parameters accordingly.

Having a troubleshooting guide can help operators address these issues swiftly, minimizing production interruptions.

Training and Best Practices

Lastly, investing in operator training is vital for effective maintenance. All personnel should be well-versed in operating the machine and understanding its maintenance needs. Best practices include:

-

Providing ongoing training sessions to update staff on new technologies and techniques.

-

Encouraging operators to report any anomalies immediately.

-

Creating a culture of safety and accountability around machine maintenance.

Well-trained operators not only enhance productivity but also extend the life of the equipment through proper care and handling.

Conclusion

In summary, the daily maintenance and upkeep of paper cup machine equipment are critical for ensuring efficiency and reliability in production. By implementing a comprehensive maintenance checklist, adhering to cleaning procedures, monitoring lubrication and electrical components, troubleshooting common issues, and investing in operator training, businesses can significantly enhance their operational performance. Regular maintenance not only prolongs the lifespan of the machinery but also contributes to higher quality products and increased safety in the workplace.

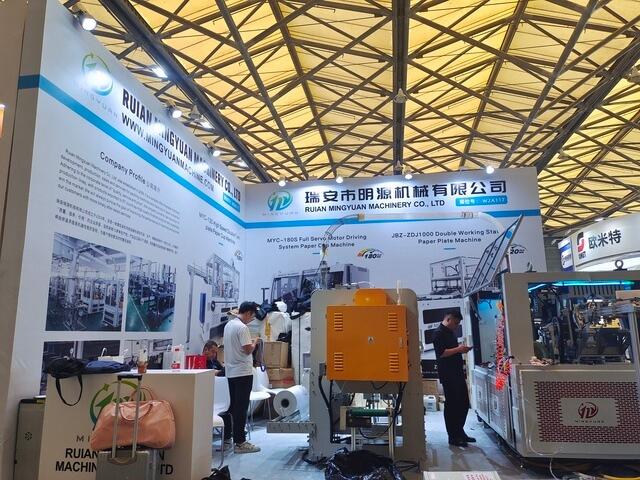

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: paperproductwholesaler@gmail.com

Email: paperproductwholesaler@gmail.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China