Technological Innovation in Paper Cup Molding Machine

Technological innovation plays a crucial role in the advancement of various industries, including the paper cup manufacturing sector. In recent years, significant developments have been made in paper cup molding machines to enhance efficiency, productivity, and sustainability. These innovations have revolutionized the way paper cups are produced, leading to higher quality products and reduced environmental impact.

1. Introduction to Paper Cup Molding Machines

Paper cup molding machines are essential equipment used in the production of disposable paper cups. These machines are responsible for shaping paperboard into cups of various sizes and designs. Traditional molding machines were manual or semi-automatic, requiring significant human intervention and leading to inconsistencies in cup quality. However, with technological advancements, modern paper cup molding machines are fully automated, ensuring precision and uniformity in cup production.

2. Automation and Robotics Integration

One of the key technological innovations in paper cup molding machines is the integration of automation and robotics. Automated machines can perform tasks such as paper feeding, heating, shaping, and stacking without the need for human intervention. Robotics further enhance efficiency by enabling precise movements and adjustments, resulting in faster production rates and reduced waste. This integration has significantly increased the overall productivity of paper cup manufacturing plants.

3. Advanced Heating and Forming Technologies

Advanced heating and forming technologies have also played a vital role in enhancing the quality of paper cups produced by molding machines. Innovations such as infrared heating systems and vacuum forming techniques ensure uniform heating and shaping of paperboard, resulting in cups with smooth surfaces and consistent thickness. These technologies have minimized defects and imperfections in the final product, meeting the stringent quality standards of the industry.

4. Eco-Friendly Materials and Processes

In response to growing environmental concerns, technological innovation in paper cup molding machines has focused on adopting eco-friendly materials and processes. Manufacturers are now using biodegradable and recyclable paperboard sourced from sustainable forestry practices. Additionally, water-based adhesives and inks are being utilized to reduce the environmental impact of cup production. These initiatives align with the global shift towards sustainable practices in manufacturing.

5. Smart Sensors and Data Analytics

The incorporation of smart sensors and data analytics in paper cup molding machines has enabled real-time monitoring and control of production processes. Sensors detect inconsistencies or abnormalities in cup formation, triggering immediate adjustments to maintain quality standards. Data analytics provide insights into production efficiency, energy consumption, and maintenance schedules, allowing manufacturers to optimize operations and reduce downtime. This intelligent technology has transformed the way paper cup manufacturing is managed.

6. Modular Design and Customization Capabilities

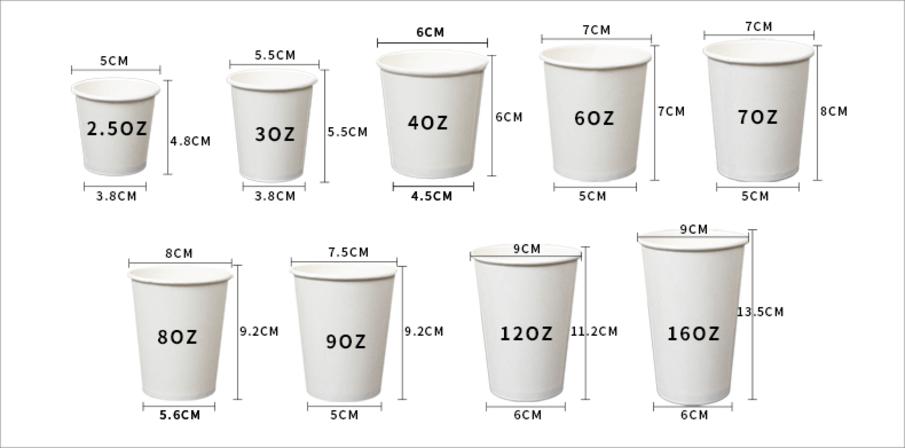

Modern paper cup molding machines feature a modular design that allows for easy customization and adaptation to varying production requirements. Manufacturers can easily switch between cup sizes, shapes, and designs by making simple adjustments to machine settings and molds. This flexibility enables greater product diversification and customization, catering to the evolving demands of the market. The modular design also simplifies maintenance and upgrades, prolonging the lifespan of the machines.

7. Energy Efficiency and Cost Savings

Technological innovations in paper cup molding machines have led to significant improvements in energy efficiency and cost savings. Newer machines are equipped with energy-saving features such as insulation systems, heat recovery mechanisms, and optimized heating elements. These innovations reduce energy consumption during the manufacturing process, resulting in lower operational costs and a smaller carbon footprint. Manufacturers benefit from both environmental sustainability and economic savings through the adoption of energy-efficient technologies.

8. Future Prospects and Industry Outlook

The future of paper cup molding machines looks promising, with ongoing research and development focused on further enhancing performance, sustainability, and automation. Emerging technologies such as 3D printing of molds, artificial intelligence for predictive maintenance, and digital twinning for virtual simulations are poised to revolutionize the industry. As consumer demand for eco-friendly and customizable paper cups continues to rise, manufacturers will need to embrace these innovations to stay competitive in the market.

Conclusion

Technological innovation in paper cup molding machines has reshaped the paper cup manufacturing industry, driving progress towards efficiency, quality, and sustainability. From automation and robotics integration to advanced heating technologies and eco-friendly practices, these innovations have propelled the industry towards a more environmentally conscious and competitive future. As the pace of technological advancement accelerates, manufacturers must continue to embrace innovation to meet evolving market demands and ensure long-term success in the dynamic landscape of paper cup production.

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China