1.How does the paper cup machine work to form paper cup?

· Raw Material Preparation The main raw material for the paper cup machine is single PE coated paper fan and bottom paper, usually treated with wax or PE laminated for food-grade use. Before putting them in the machine, the paper is cut into paper fan shape, which will be used as the side wall material of the paper cup.

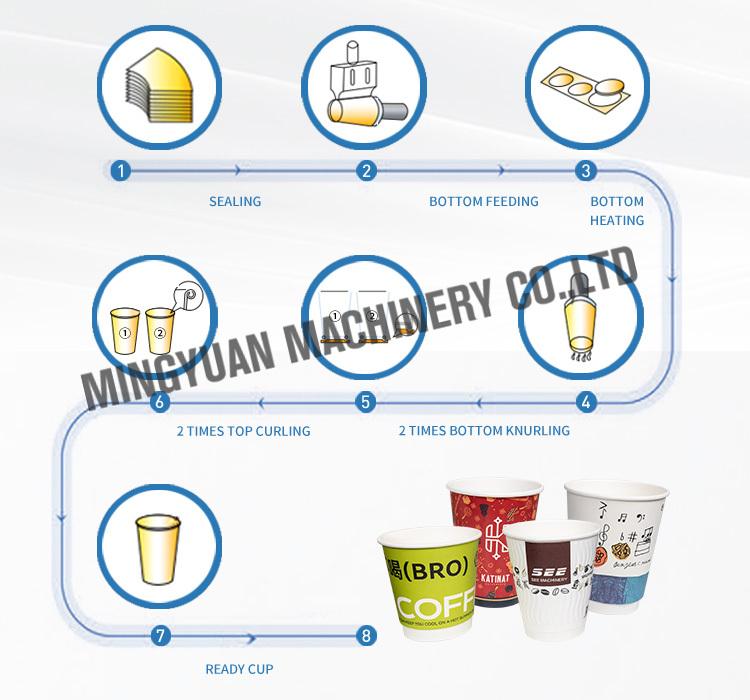

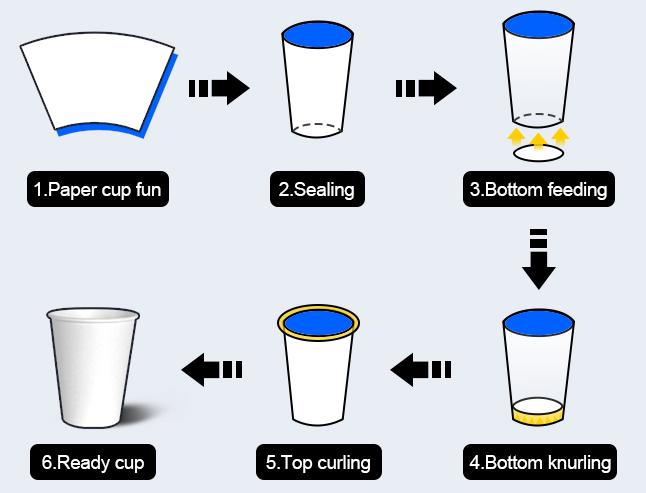

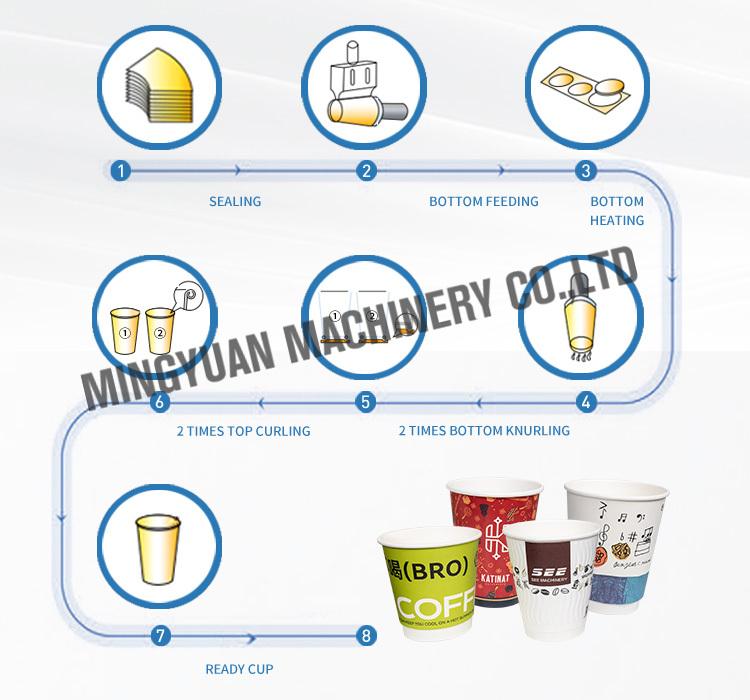

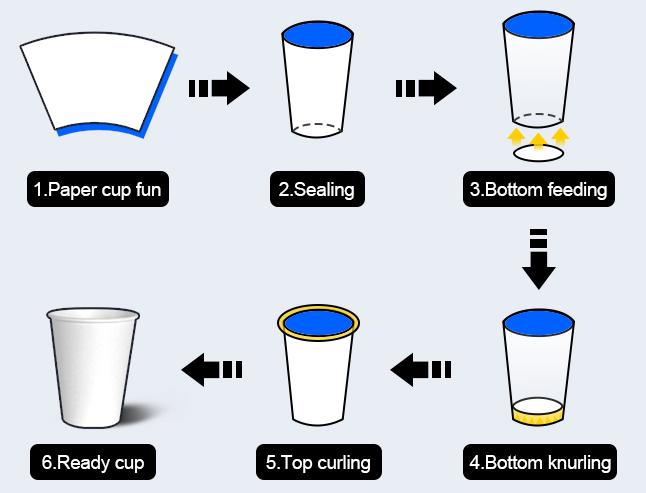

· Paper Cup Forming The paper cup machine processes the raw materials into paper cups through the following steps:

· Paper fan Feeding: The cut paper fan are fed into the machine through an automatic feeding system. The feeding system delivers the paper fan accurately into the forming section based on set dimensions and speed.

· paper side Forming: the paper fan will be formed as paper tube and sealed by ultrasonic /copper heater system

· Bottom Forming: The paper tube (cup body)is transferred to the bottom forming section. The bottom forming section presses pre-cut circular paper pieces into paper tube , and fold cup bottom and pre-heater them through bottom heater unit .

· Cup bottom Knurling : After bottom forming,the knurling heater will knurl and seal cup bottom to prevent leakage.

· Cup top rim curling: The upper edge of the paper cup is heated and rolled by the curling unit to make the rounded rim

· Heating and Bonding Throughout the forming process, the paper cup machine typically uses ultrasonic / copper heate system to seal cup side . Common bottom heating methods include hot air bottom heater and Heating oven, which melt the PE film and seal cup bottom without leakage issues

· Inspection and Output The formed paper cups go through a quality inspection system, checking aspects like appearance, size, and sealing. Once approved, the qualified paper cups are automatically output to the collection area for packaging and shipping.

· Automated Control Modern paper cup machines are equipped with PLC touch screen control systems, using Touch screen to control the entire production process, including paper feeding, forming, heating, bonding, inspection, and output. These PLC control system not only increase production efficiency but also ensure consistency and quality of the paper cups.

2.Raw materials for making paper cup

The main raw materials required to make paper cups include the following:

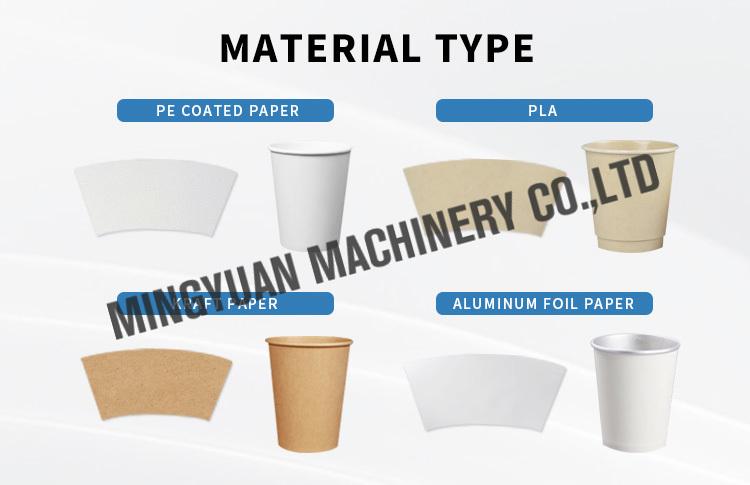

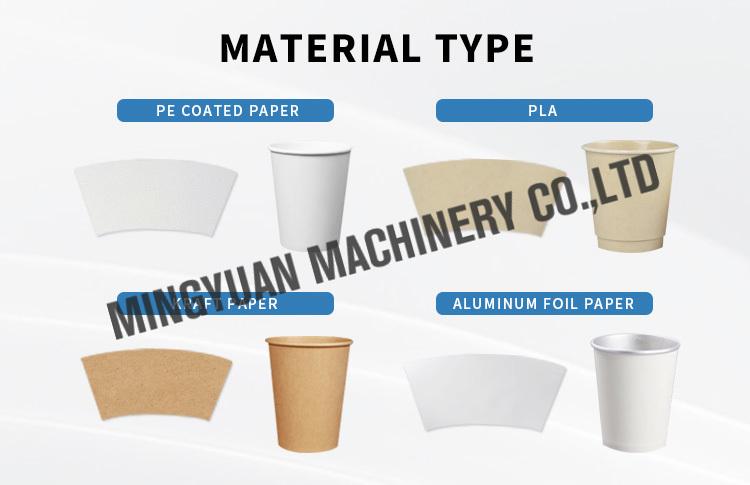

Food-grade cardboard: This is the main raw material for making paper cups. It is usually high-strength food-grade cardboard with a certain thickness and toughness. Common cardboard weight ranges from 150gsm to 350gsm, depending on the size and purpose of the paper cup.

White cardboard: often used in single-layer paper cups, with good printing effect and smoothness.

Kraft paper : It has high strength and burst resistance and is often used for paper cups that require higher durability, such as takeaway coffee cups.

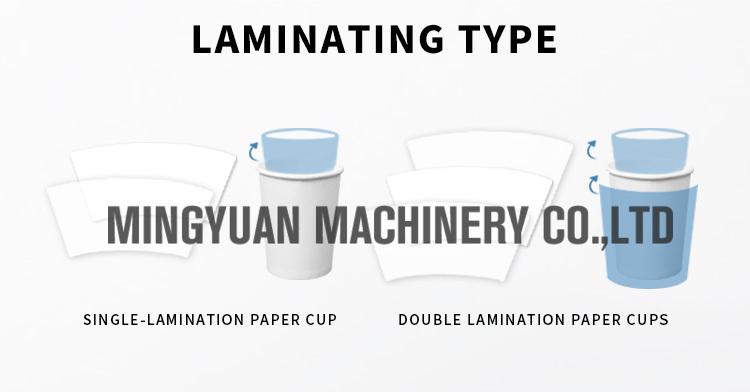

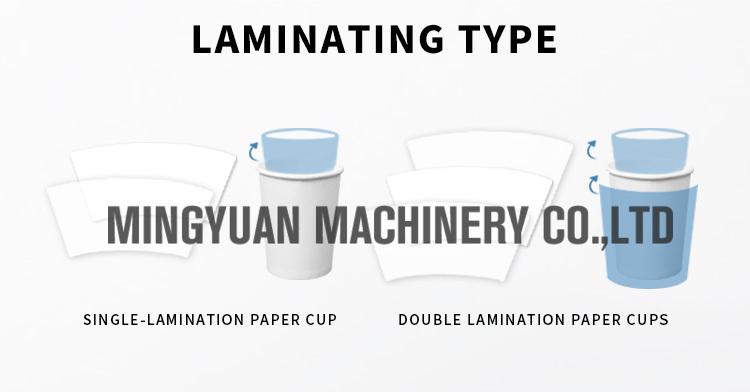

Above paper should be with with single PE/PLA laminating, ultrasonic only can seal paper with PE /PLA coating

PE coated paper

Single-sided PE coated paper: One side is covered with a layer of polyethylene (PE) film, which is mainly used for waterproofing and oil-proofing. Suitable for cold drink paper cups.

Double-sided PE coated paper: Both sides are covered with PE film, which has better waterproof and oil-proof effect. It is suitable for hot drink paper cups to prevent softening due to penetration of hot drinks.

3.How to choose the paper weight of paper cups of different sizes?

Selection of GSM for Different Sizes of Paper Cup fan

When selecting the GSM (grams per square meter) for paper cup fan, it is necessary to determine it based on the cup's capacity and usage. Below are some common paper cup sizes and recommended GSM ranges:

2-4oz Small Paper Cups

· Recommended GSM: 150gsm - 180gsm

· Usage: Suitable for small servings like espresso, sauces, and sample cups.

5-8oz Medium Paper Cups

· Recommended GSM: 180gsm - 210gsm

· Usage: Suitable for tea, coffee, and cold drinks, commonly used in offices and cafes.

9-12oz Large Paper Cups

·Recommended GSM: 210gsm - 250gsm

·Usage: Suitable for medium-sized drinks like large coffee, tea, and juice, ideal for take-out drinks.

13-16oz Extra-Large Paper Cups

·Recommended GSM: 250gsm - 300gsm

·Usage: Suitable for large servings like extra-large coffee, milk tea, and smoothies, typically used for take-out and gatherings.

Considerations for Selecting GSM for Paper Cup Blanks

· Usage Scenario: Consider the specific usage scenario and purpose of the paper cup to ensure the selected GSM meets the strength and durability requirements.

· Beverage Temperature: Hot drinks require higher GSM paper cup blanks to ensure the cup does not deform or leak; cold drinks can use slightly lower GSM blanks.

· Double-Wall Cups: For double-wall cups, the inner and outer paper cup blanks can have different GSM, with the outer layer typically slightly lower than the inner layer but ensuring overall insulation and strength.

· Coating Treatment: Consider the coating treatment of the paper cup, such as single-side PE lamination or double-side PE lamination, as the coating affects the strength and performance of the cup.

With these GSM selection recommendations, you can better match the needs of different sizes of paper cups, ensuring their performance and quality in use.

4. What equipment is needed for the paper cup production line

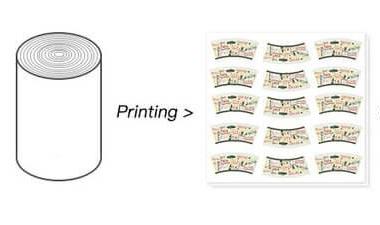

Printing machine

1.Function:Promgting patterns,logo and brand information on paper cup base paper

2.Features:Bright colors and high printing precision.Commonly used printing equipment includs flex ographic printing machine,gravure printing machine and offset printing machine.The printing machine can accurately print the pattren on the paper cup base paper according to the design requirements,providing beautiful cardboard materials for subsequent production.

2.Die-cutting machine

1. Function: Die-cut the printed paper roll into flat sheets.

2. Features: Precise and fast die-cutting to ensure that the size and shape of each paper cup fan-shaped piece are consistent. The die-cutting machine cuts the printed paper roll into flat sheets suitable for paper cup molding, providing standardized raw materials for subsequent processing.

3.Label remover

1. Function: Remove waste paper and unnecessary parts from die-cut paper.

2. Features: High efficiency, precision, suitable for mass production. The label remover can remove excess waste from paper, ensure the neatness and beauty of the paper, and improve production efficiency.

4.Paper Cup Machine

1. Function: curl the fan-shaped paper cup sheet into shape, ultrasonic /copper sealing the side edges, feed the cup bottom and bottom knurling heating sealing cup bottom.

2. Features: high degree of automation, capable of producing paper cups of various specifications, stable and reliable operation. The paper cup machine is the core equipment of the entire production line, responsible for processing paper sheets into the final paper cup product.

5.Paper cup packaging machine

1. Function: stack and package qualified paper cups for easy transportation and storage.

2. Features: fast speed, neat packaging, and customized packaging according to needs. The packaging machine can neatly stack and package the produced paper cups, providing convenience for the transportation and sales of products.

Through the reasonable configuration of the above equipment, the paper cup production line can achieve a one-stop production service from raw materials to finished paper cups. Each device has its own unique functions and characteristics, which together ensure an efficient and stable production process. This not only improves production efficiency, but also ensures product quality and consistency, meeting the market's large demand for paper cups.

5. How many paper cups of different sizes can be made from one ton of paper?

2.5oz: One ton of 140g+15pe paper can produce about 750,000 to 800,000 2.5oz paper cups.

6oz: One ton of 160g+15pe paper can produce about 300,000 to 350,000 6oz paper cups.

9oz: One ton of 240+15pe paper can produce about 150,000-170,000 9oz paper cups.

12oz: One ton of 240+15pe paper can produce about 130,000-150,000 12oz paper cups.

16oz: One ton of 280+15pe paper can produce about 80,000-100,000 16oz paper cups.

Please note that these figures are only a rough estimate and production volumes will vary depending on paper weight, production process, and other factors. The paper weight required for each size of paper cup varies, so the above data is for reference only and should not be used as a final basis for production.

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: paperproductwholesaler@gmail.com

Email: paperproductwholesaler@gmail.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China