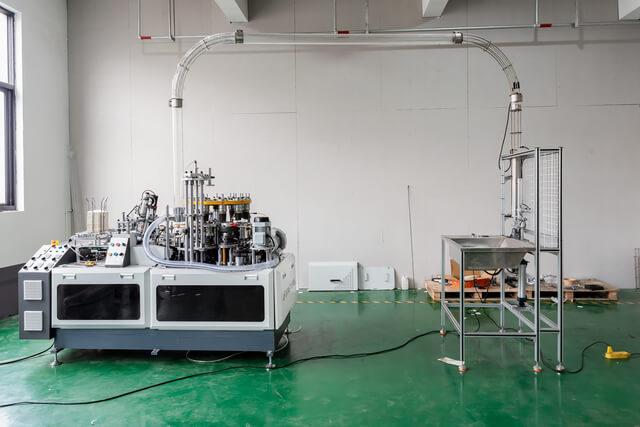

Technological innovation plays a crucial role in the development of JBZ paper cup machines, revolutionizing the production process and enhancing efficiency. With advancements in engineering and automation, JBZ paper cup machines have undergone significant transformations, making them more reliable, versatile, and sustainable than ever before.

1. Automation and Precision Engineering

The integration of automation technologies in JBZ paper cup machines has led to remarkable improvements in production speed and accuracy. Automated systems ensure precise cutting, folding, and sealing of paper cups, reducing the margin of error and increasing overall productivity. By minimizing human intervention, automation also enhances workplace safety and efficiency.

2. Advanced Material Handling

Technological innovation has enabled JBZ paper cup machines to handle a wide range of materials with ease, including different types of paper and coatings. Enhanced material handling capabilities ensure that the machines can adapt to various production requirements, allowing for greater flexibility and customization. This versatility is essential in meeting the diverse needs of customers in the paper cup industry.

3. Energy Efficiency and Sustainability

Modern JBZ paper cup machines incorporate energy-efficient components and design features to reduce power consumption and minimize environmental impact. From optimized heating systems to intelligent power management, these machines are designed to operate efficiently while maintaining high production standards. Sustainability has become a key focus in technological advancements, aligning with the global shift towards eco-friendly manufacturing practices.

4. Digitalization and Data Analytics

The integration of digital technologies and data analytics in JBZ paper cup machines enables real-time monitoring, predictive maintenance, and performance optimization. By collecting and analyzing data on machine operations, manufacturers can identify opportunities for improvement, prevent breakdowns, and enhance overall reliability. This data-driven approach allows for proactive decision-making and continuous enhancement of machine efficiency.

5. Remote Monitoring and Control

Remote monitoring and control capabilities have revolutionized the way JBZ paper cup machines are managed and maintained. Through remote access interfaces, operators can monitor machine performance, troubleshoot issues, and adjust settings from anywhere in the world. This remote connectivity not only improves operational efficiency but also enables timely interventions to prevent downtime and optimize production processes.

6. User-Friendly Interface and Automation

Technological advancements have led to the development of user-friendly interfaces in JBZ paper cup machines, simplifying operation and maintenance tasks. Intuitive touchscreens, automated setup procedures, and interactive guides make it easier for operators to control and configure the machines effectively. This user-centric approach enhances usability and reduces training time for new operators.

7. Modular Design and Scalability

The modular design of JBZ paper cup machines allows for easy customization, expansion, and scalability based on changing production demands. Manufacturers can easily upgrade or reconfigure machine components to accommodate new cup sizes, designs, or production volumes. This flexibility ensures that JBZ paper cup machines remain adaptable and future-proof in the dynamic market landscape.

8. Continuous Innovation and Industry Leadership

With a commitment to continuous innovation, JBZ paper cup machine manufacturers strive to stay at the forefront of technological advancements and industry trends. By investing in research and development, collaborating with technology partners, and listening to customer feedback, these companies drive progress and set new standards in paper cup machine development. Their leadership in technological innovation propels the industry forward and shapes the future of paper cup production.

Conclusion: Driving Efficiency and Sustainability

Technological innovation has transformed JBZ paper cup machines into advanced, efficient, and sustainable manufacturing solutions. Through automation, material handling improvements, energy efficiency measures, digitalization, and user-friendly interfaces, these machines offer unprecedented capabilities and benefits to manufacturers. By embracing continuous innovation and industry leadership, JBZ paper cup machine developers pave the way for a more efficient and sustainable future in paper cup production.

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China