Paper cup production machines are essential equipment for producing paper cups in various sizes and designs. These machines play a crucial role in the manufacturing process, providing numerous advantages and features that contribute to efficient and high-quality production. In this article, we will explore the product advantages and features of paper cup production machines, shedding light on their capabilities and benefits.

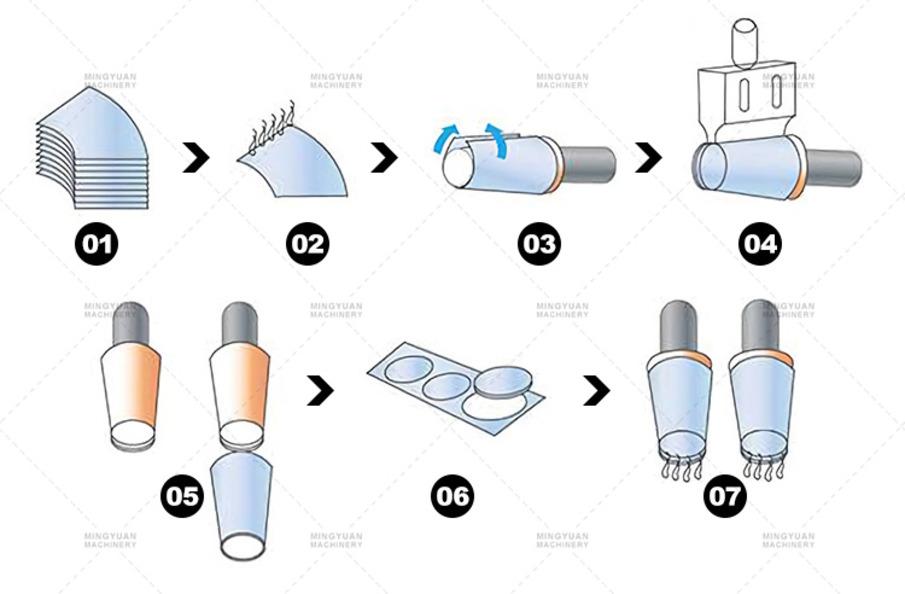

1. Automated Production Process

One of the primary advantages of paper cup production machines is their ability to automate the entire production process. These machines are equipped with advanced technology and control systems that enable seamless automation of cup forming, cutting, and shaping, significantly reducing the need for manual intervention. As a result, manufacturers can achieve higher production volumes with consistent quality, leading to increased efficiency and cost savings.

2. Versatility in Cup Sizes and Designs

Paper cup production machines offer a wide range of flexibility in producing various cup sizes and designs to meet diverse market demands. Whether it's standard coffee cups, large beverage containers, or custom-designed cups for promotional purposes, these machines can be adjusted to accommodate different specifications. The versatility of these machines allows manufacturers to cater to a broader customer base and adapt to changing trends in the food and beverage industry.

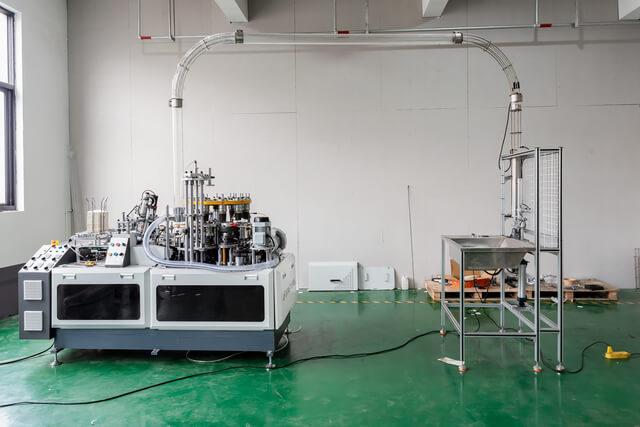

3. High-Speed Production Capability

With their advanced technology and precision engineering, paper cup production machines are capable of high-speed production, ensuring rapid output without compromising on quality. These machines can consistently produce a large number of paper cups within a short period, making them ideal for meeting tight production deadlines and addressing sudden surges in demand. The high-speed capability contributes to enhanced productivity and responsiveness to market requirements.

4. Energy Efficiency and Environmental Sustainability

Modern paper cup production machines are designed with a focus on energy efficiency and environmental sustainability. By incorporating energy-saving features and optimized processes, these machines minimize energy consumption while maximizing output, resulting in lower operational costs and reduced environmental impact. Furthermore, the use of biodegradable and recyclable materials in the production process aligns with sustainable practices, appealing to eco-conscious consumers and businesses.

5. User-Friendly Operation and Maintenance

The user interface and operation of paper cup production machines are engineered for ease of use, allowing operators to control and monitor the production process with minimal training. Additionally, these machines are designed for convenient maintenance, with accessible components and automated diagnostic systems that facilitate troubleshooting and upkeep. The user-friendly nature of these machines contributes to overall operational efficiency and reduces downtime associated with maintenance tasks.

6. Quality Assurance and Consistency

Quality assurance is paramount in paper cup production, and these machines are equipped with features to ensure consistent quality throughout the manufacturing process. From precise cup forming to accurate printing and finishing, these machines maintain strict quality standards, resulting in uniform and reliable output. Manufacturers can have confidence in the consistency of their products, enhancing their reputation and customer satisfaction.

7. Integration with Industry 4.0 Technologies

Leading-edge paper cup production machines are designed to integrate with Industry 4.0 technologies, enabling connectivity, data analytics, and predictive maintenance capabilities. This integration empowers manufacturers to gather real-time production data, optimize processes, and preemptively address potential issues, fostering a more agile and responsive production environment. By embracing digital innovation, these machines position manufacturers for long-term competitiveness and adaptability.

8. Customization and Add-On Features

Manufacturers can benefit from the customization options and add-on features available with paper cup production machines, tailoring the equipment to suit specific production requirements. Whether it's incorporating branding elements into the cup design, implementing specialized coatings, or integrating packaging solutions, these machines offer a range of customization possibilities. Such tailored features enable manufacturers to differentiate their product offerings and cater to niche market segments.

Conclusion

In conclusion, paper cup production machines present a multitude of advantages and features that contribute to efficient, high-quality production processes. From automation and versatility to energy efficiency and customization, these machines empower manufacturers to meet market demands with precision and reliability. As the demand for sustainable and innovative packaging solutions continues to rise, the role of advanced paper cup production machines becomes increasingly vital in driving the industry forward.

```

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: paperproductwholesaler@gmail.com

Email: paperproductwholesaler@gmail.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China