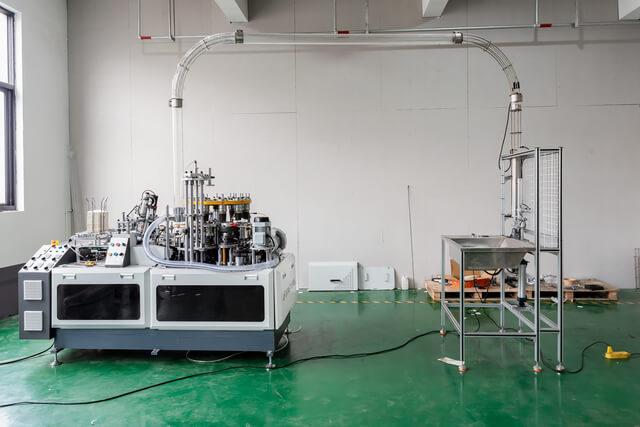

Paper cup and paper plate making machines are essential equipment for the production of disposable paper cups and plates, which are widely used in the food and beverage industry. To ensure the efficient and smooth operation of these machines, proper maintenance is crucial. In this article, we will provide comprehensive maintenance tips for paper cup and paper plate making machines to help you prolong the lifespan of the equipment and maintain high production quality.

1. Regular Cleaning

Regular cleaning is essential for maintaining the efficiency and hygiene of paper cup and plate making machines. Remove any residual paper dust, adhesive, or lubricant from the machine components using appropriate cleaning agents and tools. Pay special attention to the molds, die-cutting tools, and conveyor belts to prevent buildup that can affect the quality of the final products.

2. Lubrication of Moving Parts

Proper lubrication of the moving parts such as bearings, chains, and gears is critical to reduce friction and wear. Use recommended lubricants and follow the manufacturer's guidelines for the frequency of lubrication. Over-lubrication should be avoided as it can attract dust and debris, leading to potential malfunctions.

3. Inspection of Electrical Components

Regularly inspect the electrical components, including wiring, switches, and control panels, for any signs of wear, damage, or overheating. Loose connections should be tightened, and any faulty components should be replaced promptly to prevent electrical hazards and machine breakdowns.

4. Calibration of Sensors and Controls

Ensure that the sensors and controls responsible for regulating the machine's operation are properly calibrated. Any misalignment or inaccurate settings can lead to production errors and material wastage. Periodic calibration and adjustment are necessary to maintain precision and consistency in the manufacturing process.

5. Replacement of Worn-out Parts

Monitor the condition of wear-prone parts such as cutting blades, forming molds, and heating elements. Replace these parts at regular intervals or when signs of deterioration are observed to prevent production issues and maintain product quality. Keeping spare parts on hand can minimize downtime during replacements.

6. Training and Monitoring of Operators

Provide comprehensive training to machine operators on the proper operation and maintenance procedures. Encourage them to conduct routine visual inspections and report any abnormalities promptly. Establish a system for monitoring and recording maintenance activities to ensure accountability and adherence to maintenance schedules.

7. Environmental Control

Control the operating environment of the paper cup and plate making machines to optimize performance and durability. Maintain suitable temperature and humidity levels to prevent moisture-related issues and corrosion. Implement dust control measures to minimize the accumulation of airborne particles that can interfere with the machinery.

8. Documentation and Records

Maintain detailed records of maintenance activities, including cleaning schedules, lubrication routines, part replacements, and equipment inspections. Documenting these activities facilitates proactive maintenance planning, identifies recurring issues, and supports troubleshooting efforts when problems arise.

Conclusion

Effective maintenance practices are integral to the reliable operation and longevity of paper cup and paper plate making machines. By following the maintenance tips outlined in this article, you can optimize the performance of the equipment, minimize downtime, and uphold the quality of the manufactured products. Regular cleaning, lubrication, inspection, and proactive replacement of parts are key elements in ensuring the smooth functioning of these essential machines.

```

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: paperproductwholesaler@gmail.com

Email: paperproductwholesaler@gmail.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China