-

Overview of Paper Cup and Paper Plate Making Machine. Raw Material Preparation. Printing and Design. Heating and Forming. Trimming and Finishing. Quality Control. Packaging and Stacking. Maintenance and Cleaning. Conclusion....

Paper Cup Making Machine

-

1. Automated Production Process. 2. Versatility in Cup Sizes. 3. Speed and Efficiency. 4. Customization Options. 5. Energy Efficiency. 6. Easy Maintenance and Cleaning. 7. User-Friendly Interface. 8. Quality Assurance. Conclusion....

Coffee Cup Manufacturing Machine

-

1. Raw Material Preparation. 2. Design and Engineering. 3. Precision Machining. 4. Component Assembly. 5. Electrical Integration. 6. Testing and Quality Assurance. 7. Finishing and Surface Treatment. 8. Packaging and Shipping. Conclusion....

Paper Cup Molding Machine

-

Introduction. Advanced Design and Components. Efficient Paper Feeding and Forming. Integrated Quality Control Systems. Environmental Sustainability Features. Enhanced User Interface and Control Systems. Increased Production Capacity. Conclusion....

Latest Paper Cup Making Machine

-

1. Automated Production Process. 2. Versatile Cup Designs. 3. Cost-Effective Solution. 4. High Production Capacity. 5. Quality Assurance. 6. Easy Operation and Maintenance. 7. Eco-Friendly Features. 8. Customization Options. In Conclusion....

Disposable Cup Machine

-

1. Design and Planning. 2. Material Selection. 3. Fabrication of Components. 4. Assembly. 5. Testing and Quality Control. 6. Calibration and Adjustment. 7. Packaging and Shipping. 8. Installation and Training. Conclusion....

mini paper cup making machine

-

1. High-Quality Material. 2. Insulation Properties. 3. Customization Options. 4. Eco-Friendly Solutions. 5. Convenient and Portable. 6. Versatility in Size and Design. 7. Cost-Effective Solution. 8. Hygienic and Safe. Conclusion....

paper cup making machine

-

1. Raw Material Preparation. 2. Printing and Cutting. 3. Cup Forming. 4. Bottom Sealing. 5. Rim Curling. 6. Quality Inspection. 7. Packaging. 8. Maintenance and Cleaning. Conclusion....

high speed paper cup making machine

-

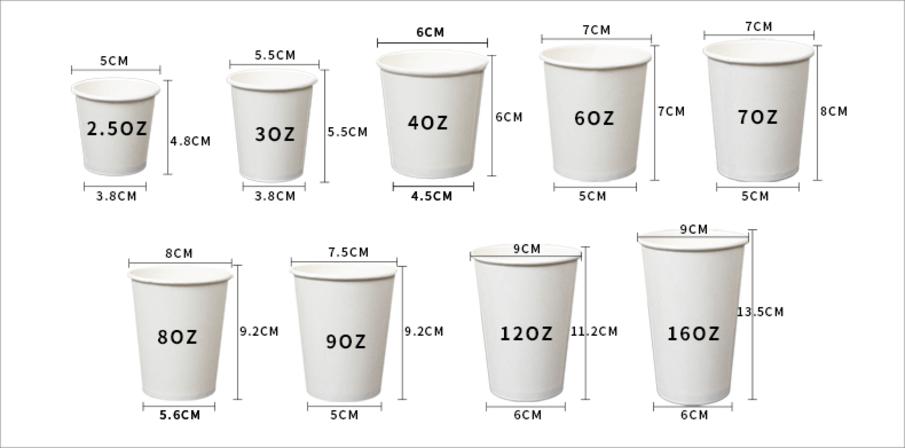

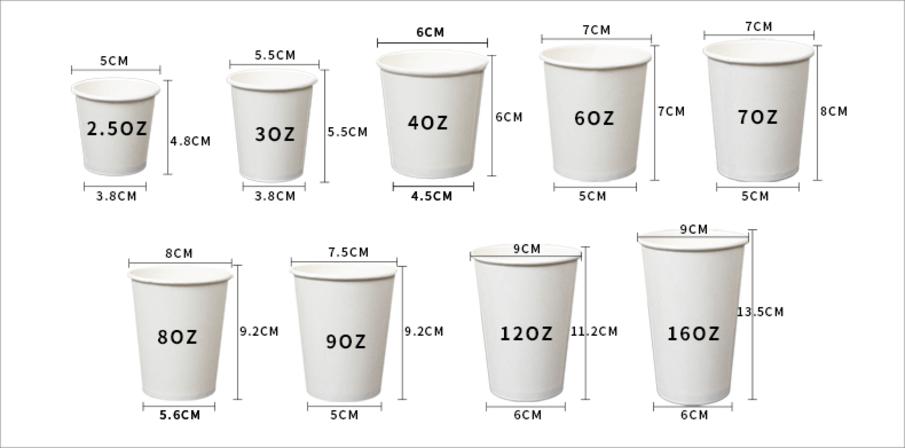

1. Efficient Production Capacity. 2. Versatility in Product Sizes. 3. Sustainable Material Usage. 4. Cost-Effectiveness. 5. Enhanced Customization and Branding Opportunities. 6. User-Friendly Operation and Maintenance. 7. Compliance with Quality and Safety Standards. 8. Integration of Advanced Technology. Conclusion....

Paper Cup and Plate Making Machine

-

1. Automation Revolutionizing Production. 2. Integration of Robotics for Enhanced Efficiency. 3. Smart Technologies for Real-Time Monitoring. 4. Sustainable Innovations for Environmental Conservation. 5. Precision Engineering for Consistent Quality. 6. Flexibility in Design and Customization. 7. Improved Safety Features for Operator Protection. 8. Continuous...

High Speed Paper Cup Making Machine

-

1. Automated Production Process. 2. Versatility in Cup Sizes and Designs. 3. High-Speed Production Capability. 4. Energy Efficiency and Environmental Sustainability. 5. User-Friendly Operation and Maintenance. 6. Quality Assurance and Consistency. 7. Integration with Industry 4.0 Technologies. 8. Customization and Add-On Features. Conclusion....

Paper Cup Production Machine

-

Introduction. 1. Automation and Efficiency. 2. Advanced Material Handling. 3. Energy Efficiency. 4. Quality Control and Monitoring. 5. Smart Manufacturing Solutions. 6. Customization and Flexibility. 7. Sustainability Initiatives. Conclusion....

Paper Cup Moulding Machine

-

Efficiency and Productivity. Versatility in Cup Sizes. Quality Control. Cost-Effectiveness. Ease of Operation. Energy Efficiency. Maintenance and Durability. Customization Options. Conclusion....

Paper Cup Manufacturing Machine

-

1. Biodegradable Materials. 2. Coating Technologies. 3. Recyclable Fibers. 4. Nanotechnology Applications. 5. Smart Packaging Solutions. 6. Barrier Coatings. 7. Automation and Efficiency. 8. Sustainable Practices. Conclusion....

Paper Cup Making Machine Raw Material

-

Introduction. Enhanced Precision with Laser Cutting Technology. Advanced Materials for Durability. Optimization of Die Design for Efficiency. Integration of Smart Technologies. Focus on Sustainability and Eco-Friendly Practices. Improved Safety Features. Collaboration with Digital Printing Technologies. Conclusion....

Paper Cup Die

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: paperproductwholesaler@gmail.com

Email: paperproductwholesaler@gmail.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China