paper cup making machine are an essential part of our daily lives, offering convenience and sustainability in beverage consumption. However, one significant challenge faced by manufacturers and consumers alike is ensuring leak-proof performance. This article will explore various methods to improve the leak-proof capabilities of paper cups, addressing material selection, design innovations, manufacturing processes, and additional coatings. By understanding these factors, we can enhance user experience and reduce environmental impact.

Choosing the Right Materials

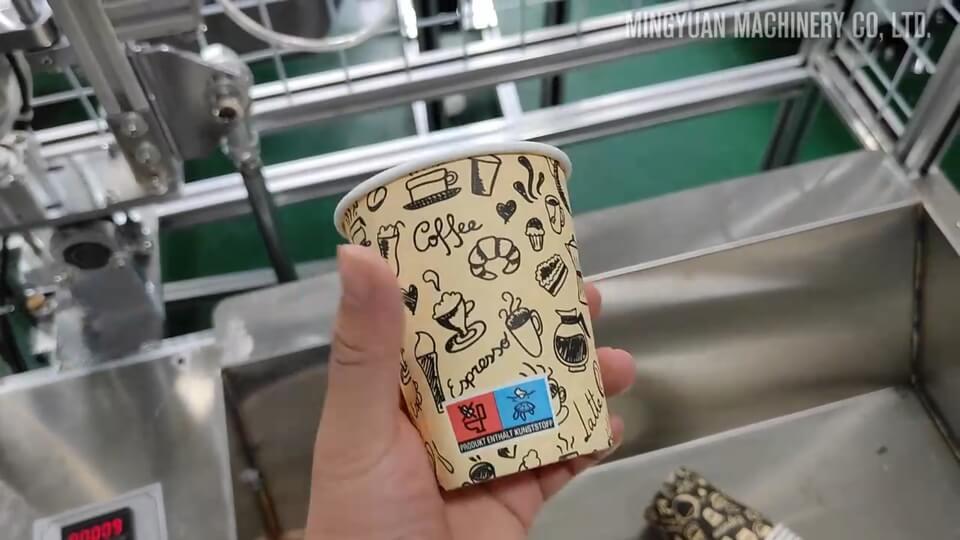

One of the most critical aspects of improving the leak-proof performance of paper cup making machine lies in the selection of materials. Traditional paper alone is porous and may not effectively contain liquids. To counter this, manufacturers often incorporate a polyethylene lining, which offers a barrier against liquid penetration. However, advancements in material science have led to the development of alternative biodegradable coatings that provide similar benefits without harming the environment. For example, polylactic acid (PLA) is a popular choice as it is made from renewable resources and offers excellent moisture resistance. By opting for high-quality, innovative materials, manufacturers can significantly enhance the leak-proof capabilities of paper cups.

Innovative Design Features

The design of paper cup making machine plays a crucial role in their leak-proof performance. Engineers and designers are increasingly looking at structural innovations to enhance durability. One effective strategy is to create double-walled cups that provide an extra layer of protection against leaks. This additional wall also helps in maintaining the temperature of hot beverages, adding to the overall user experience. Furthermore, incorporating ribbed or textured surfaces can increase grip and prevent slippage, reducing the likelihood of accidents that can lead to spills. By focusing on intelligent design, manufacturers can produce paper cups that withstand pressure and maintain their integrity over time.

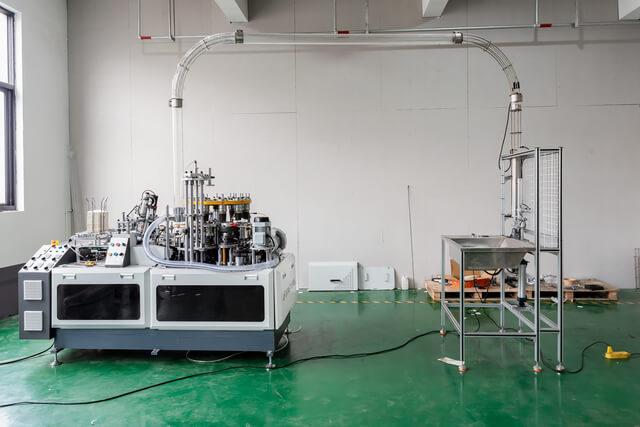

Advancements in Manufacturing Processes

Manufacturing processes significantly impact the overall quality and performance of paper cup making machine. Implementing precision techniques such as automated molding and forming can ensure consistent thickness and sealing of the cup, which are vital for preventing leaks. Additionally, modern technologies like ultrasonic sealing can create stronger bonds between materials, enhancing the cup's ability to hold liquids without leaking. By investing in advanced manufacturing technologies, companies can improve the structural integrity of their products and minimize defects that contribute to leakage.

Coatings and Treatments

Applying effective coatings is another method to enhance the leak-proof performance of paper cups. In addition to traditional polyethylene, there are eco-friendly options available that do not compromise on performance. These coatings can provide a waterproof barrier while being recyclable or compostable. Advanced treatments such as wax coatings or bio-based films can also be applied to offer moisture resistance without adding significant weight. Selecting the right coating material can greatly influence the cup's ability to contain liquids without leaking, thus meeting consumer needs for both functionality and sustainability.

Testing and Quality Control

To ensure that paper cup making machine meet the required leak-proof standards, rigorous testing and quality control measures are essential. Manufacturers should implement comprehensive testing protocols that simulate real-life usage scenarios. This includes assessing the cups under various temperatures and pressures to determine their leak resistance. Regular quality checks throughout the production process can help identify potential weaknesses early, allowing for adjustments before the final product reaches consumers. Establishing stringent quality control measures ensures that only high-performing cups make it to the market, ultimately improving customer satisfaction.

Consumer Education and Awareness

While manufacturers play a crucial role in enhancing the leak-proof performance of paper cup making machine, consumer education is equally important. Informing consumers about the proper use and disposal of paper cups can help mitigate issues related to leaks. For instance, encouraging users to avoid overfilling cups or using them for beverages that exceed recommended temperatures can lead to better experiences. Additionally, promoting awareness around the types of paper cups available—especially those that are designed with improved leak-proof performance—can guide consumers towards making informed choices that align with their needs.

Conclusion

Improving the leak-proof performance of paper cup making machine involves a multifaceted approach that encompasses material selection, design innovation, manufacturing processes, and effective coatings. By focusing on these areas, manufacturers can create high-quality products that meet the demands of both consumers and the environment. As technology continues to advance, the potential for developing even more effective solutions remains promising. Ultimately, collaboration between manufacturers, consumers, and the broader community is essential to drive improvements in this crucial aspect of paper cup production.

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China