Printing your logo on paper cups is an effective way to promote your brand while providing a practical product for customers. With the advances in technology, paper cup machines have made it easier than ever to customize cups with high-quality graphics. This article will explore the process of printing logos on paper cups, the technologies involved, and the benefits of branding through this medium.

Understanding Paper Cup Machines

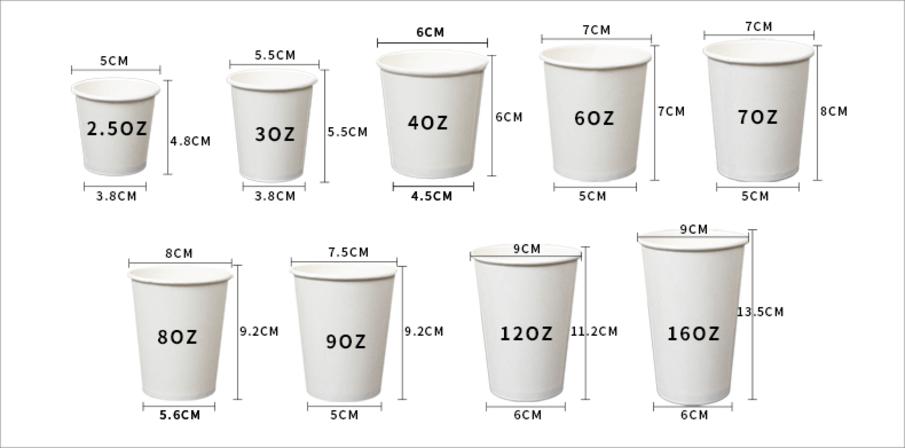

Paper cup machines are specialized equipment designed to manufacture paper cups efficiently. These machines can produce various sizes and types of cups, including single-wall, double-wall, and insulated designs. The production process involves several steps, including feeding paper rolls, forming the cups, and applying coatings for insulation and moisture resistance. Understanding how these machines work is crucial for successfully integrating logo printing into the production process.

Choosing the Right Printing Method

There are several printing methods available for applying logos to paper cups. The most common techniques include flexographic printing, offset printing, and digital printing. Each method has its pros and cons, making it essential to choose one that fits your needs and budget.

Flexographic printing is often favored for large production runs due to its speed and cost-effectiveness. It uses flexible relief plates to transfer ink onto the cups, allowing for vibrant colors and intricate designs. Offset printing, on the other hand, provides high-quality images and is suitable for smaller batches. Digital printing has gained popularity for its ability to handle short runs and complex designs without the need for plates, making it an ideal choice for custom orders.

Designing Your Logo

Before printing, it's crucial to design your logo with the printing process in mind. Consider the size, color, and placement of your logo on the cup. Ensure that your design is scalable and looks great in both small and large formats. A vector file format is typically preferred for printing as it allows for resizing without losing quality.

Additionally, think about the colors you want to use. Different printing methods may handle colors differently, so consult with your printer to ensure your design translates well across various mediums. It's also advisable to request a sample print to visualize how your design will appear on the final product before committing to a full production run.

Integrating Printing into the Production Process

Once your logo design is finalized, it’s time to integrate printing into the production process of the paper cups. This typically involves coordinating with the manufacturer of the paper cup machine to ensure that the printing setup aligns with their production line. This step is critical, as it ensures that the cups are printed correctly during manufacturing without causing delays or complications.

The integration process may involve adjusting the machine settings, such as the speed and ink flow, to accommodate the specific requirements of your logo print. Close collaboration with the operator can lead to optimal results, ensuring that the final product meets your expectations.

Quality Control Measures

Implementing quality control measures during the printing process is essential to ensure that each cup meets your standards. This includes checking for color accuracy, alignment, and overall print quality. Regular inspections during production can help identify any issues early, preventing waste and ensuring consistency across the batch.

It’s also wise to establish clear communication with your printing service provider. Discussing potential challenges and setting guidelines for quality checks can lead to smoother operations and better end products. Having a reliable quality assurance protocol in place will significantly enhance your brand's reputation.

The Benefits of Custom Printed Paper Cups

Custom printed paper cups offer numerous benefits for businesses. Firstly, they serve as a mobile advertisement. Every time a customer uses a cup, they are promoting your brand to everyone around them. This visibility can be particularly advantageous at events, festivals, or busy locations.

Secondly, branded cups enhance customer experience by adding a personal touch. Customers appreciate quality packaging that reflects your brand values and aesthetics. Furthermore, using environmentally friendly materials can elevate your brand image, attracting consumers who prioritize sustainability.

Finally, offering unique designs can differentiate your product in a crowded market. Creative and eye-catching cups can attract attention and encourage trial, leading to increased sales and customer loyalty.

Conclusion

Printing your logo on paper cups produced by paper cup machines is an excellent strategy for enhancing brand visibility and customer engagement. By understanding the printing methods available, designing an appealing logo, and integrating quality control measures into the production process, you can ensure that your custom cups reflect your brand's identity effectively. The investment in branded paper cups pays off by promoting your business and creating a memorable experience for your customers. Embrace the potential of custom printed cups and watch your brand recognition soar.

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: paperproductwholesaler@gmail.com

Email: paperproductwholesaler@gmail.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China