Part 1: Delivery time, after-sales service and paper cup machine parameters introduction

During the initial communication with us, we will give priority to introducing you to the delivery time, after-sales service details and main parameters of the relevant models that you are most concerned about. This information will help you better understand our products and services and support your decision-making.

The 25-30 days delivery period covers raw material procurement, paper cup design, paper cup machine production, commissioning, quality inspection, as well as packaging and logistics arrangements. In addition, we also provide comprehensive after-sales services such as installation and commissioning services, operation training, two-year warranty, regular inspections, problem solving, and operation and maintenance manuals to ensure the stable operation and efficient production of your equipment.

Part 2: Customer demand analysis and paper cup machine recommendation

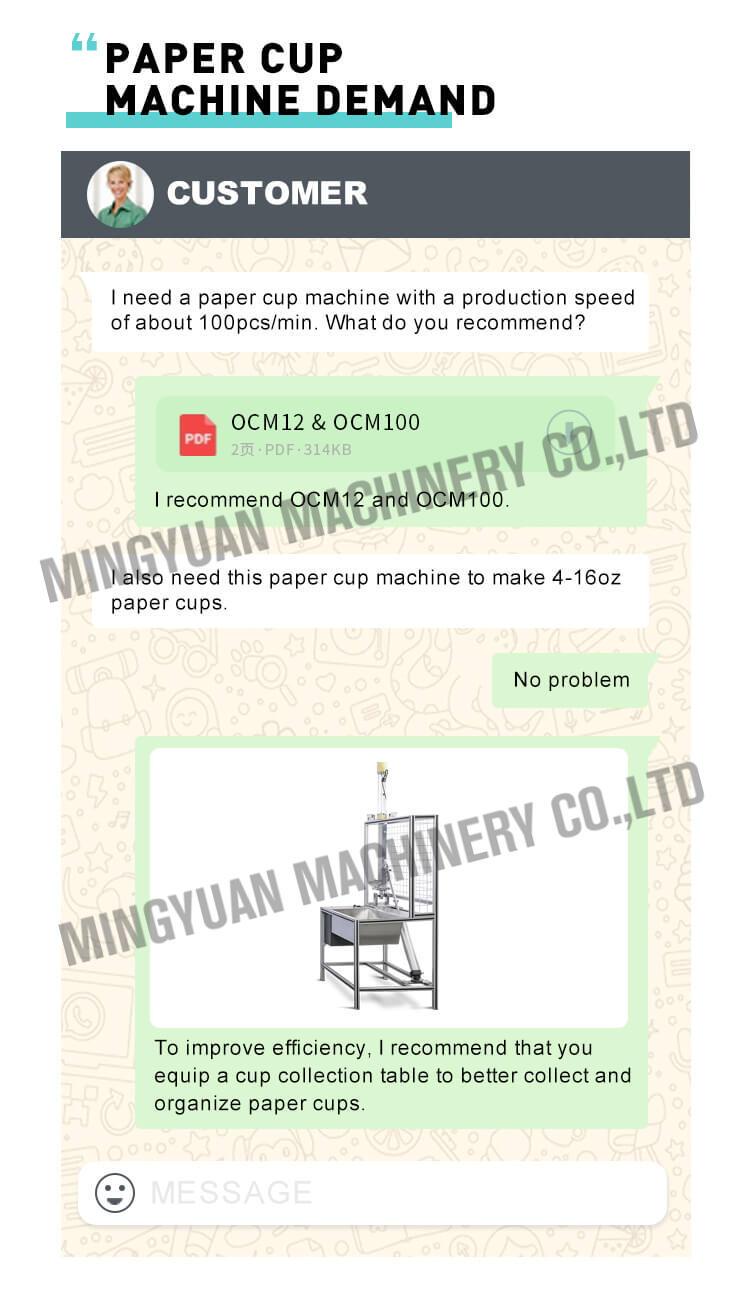

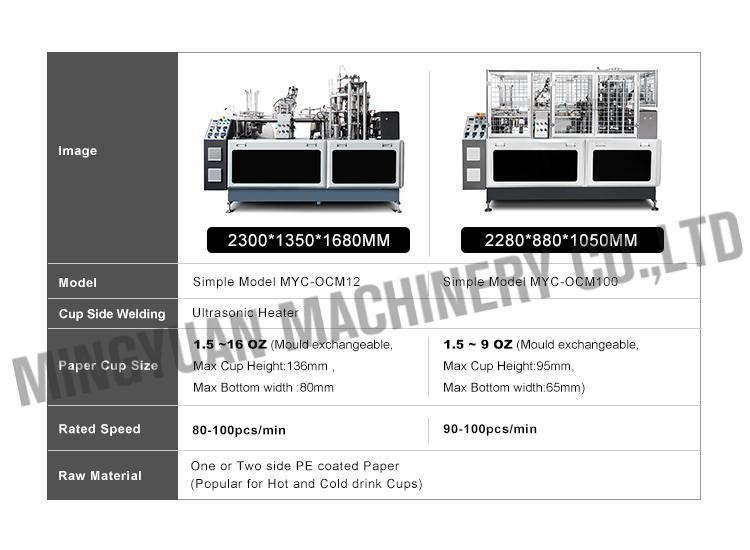

When choosing a paper cup machine, customers usually have some specific requirements. In our case, the paper cup machine required by the customer must be able to produce paper cups of 4 to 16 ounces, and the production speed must reach 100 paper cups per minute. Based on these requirements, we recommended two paper cup machines: OCM12 and OCM100.

1. Customer demand for paper cups: The customer requires the paper cup machine to be able to produce paper cups with specifications ranging from 4 to 16 oz, and the production speed must reach 100 paper cups per minute. In addition, the customer hopes that the machine will be equipped with a cup collection rack to improve the level of automation. The customer has high requirements for the quality of paper cups, especially in terms of dimensional accuracy and production consistency, to ensure that each paper cup meets the standards.

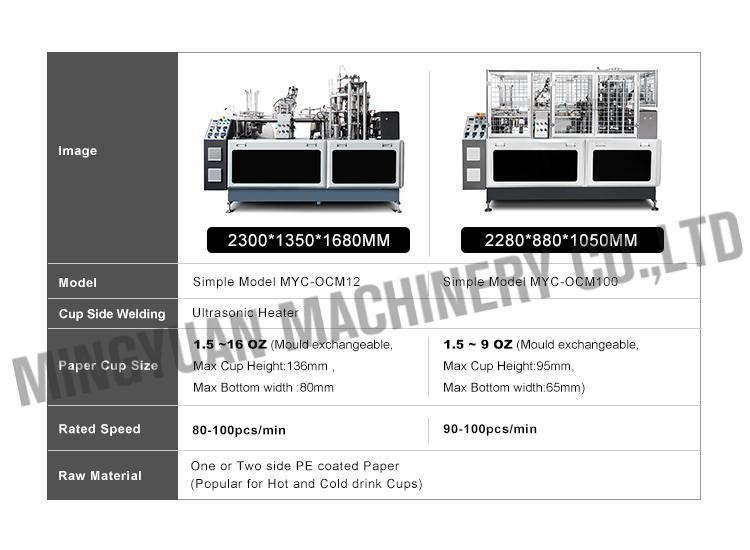

2. Recommended machine models: We offer two paper cup machines as options:

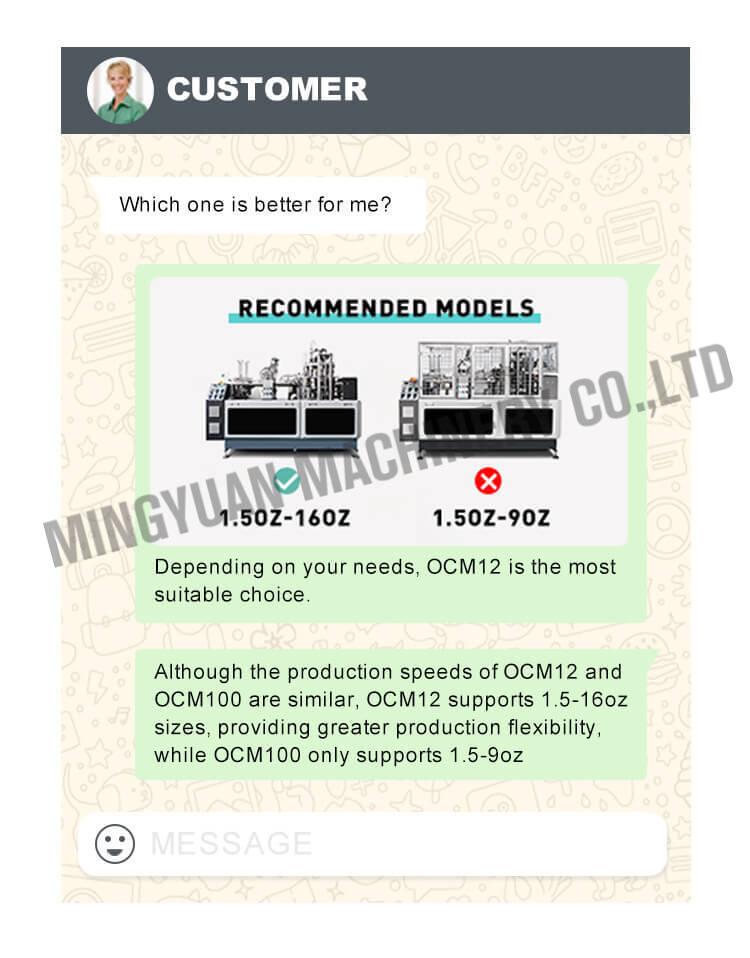

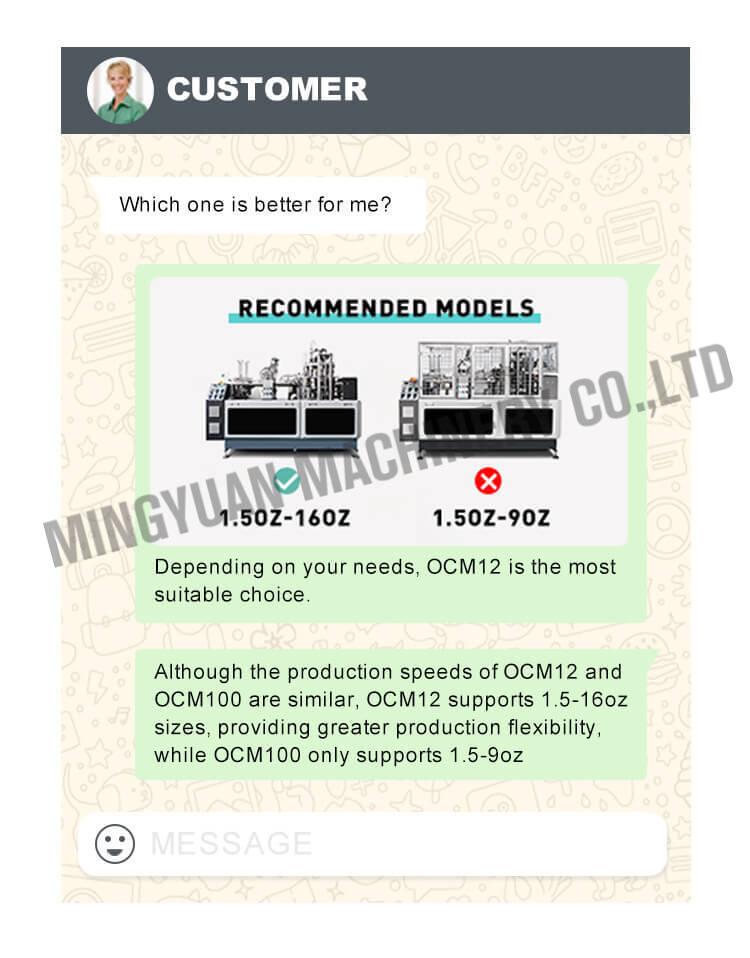

OCM12: This machine is capable of producing paper cups from 1.5 to 16 ounces, which fully meets the customer's needs. Its production speed is also around 100 paper cups per minute, which can meet the customer's requirements for production efficiency.

OCM100: Although the production speed of this machine is also close to 100 paper cups per minute, its production range is limited to 1.5 to 9 ounces, which does not meet the maximum 16 ounces specification required by customers.

3. Final recommendation: After evaluating the characteristics of the two machines, we recommend that customers choose OCM12. Although the speed of OCM100 also meets the requirements, its production range is limited to 9 ounces, which is not suitable for customers' paper cup size needs. OCM12 not only covers all the size ranges required by customers, but also has the required production speed, ensuring that it can fully meet customers' production needs.

Through such a recommendation process, we ensure that customers can choose the paper cup machine model that best meets their needs, thereby improving production efficiency and product quality.

Part 3: Customized Paper Cup Service

In the custom paper cup service, we are committed to providing each customer with personalized and high-quality solutions. The following is the detailed process of our service:

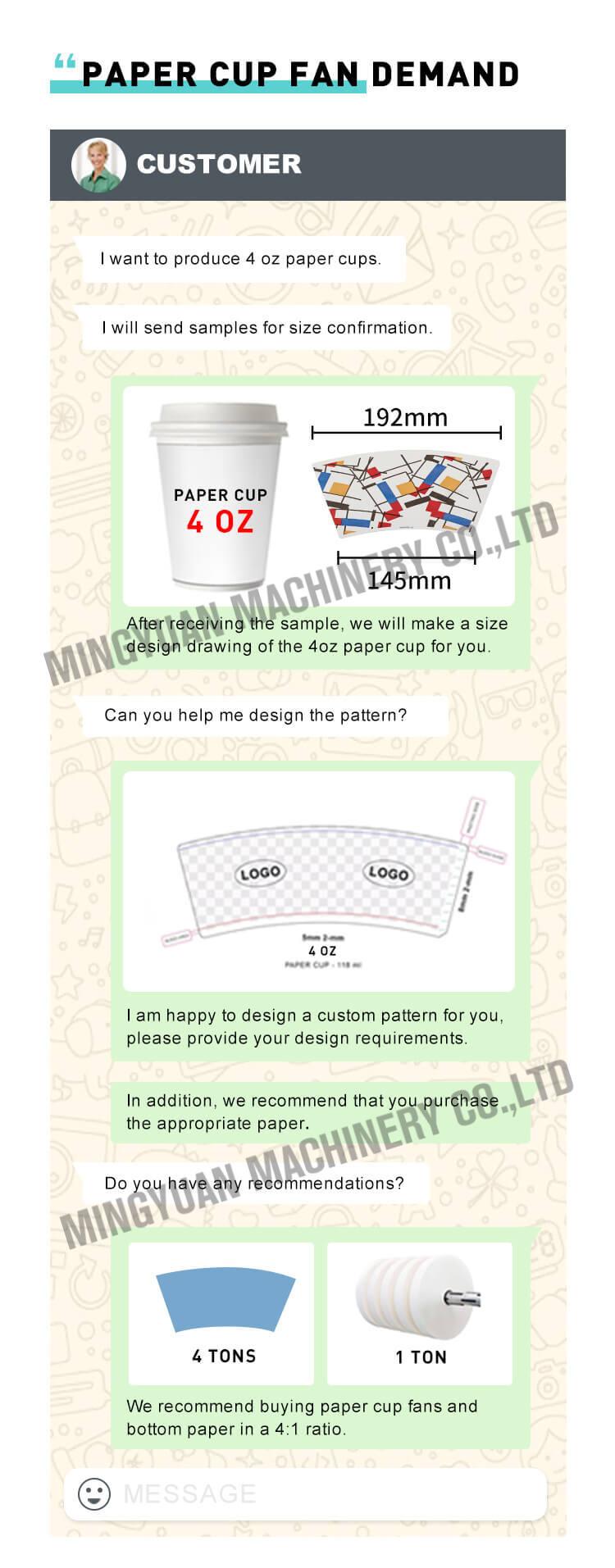

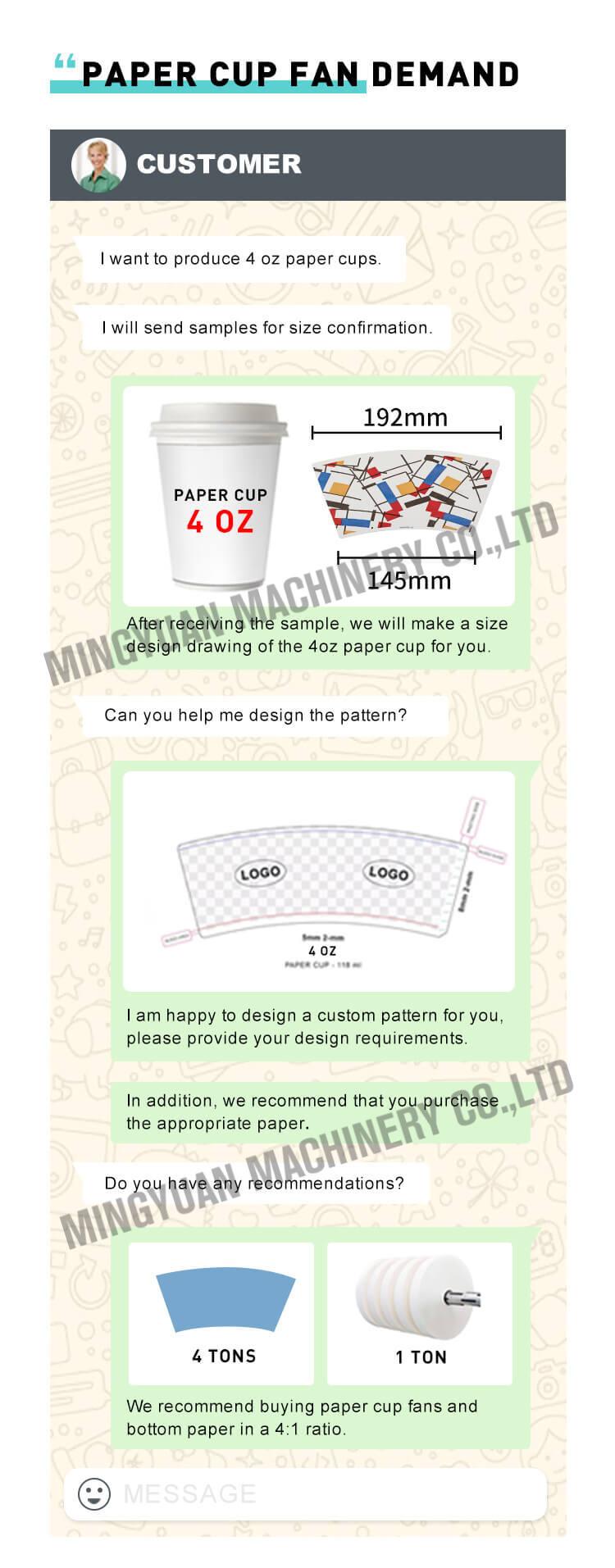

Design requirements confirmation: The customer needs us to produce paper cup fans for 4-ounce paper cups, and will send samples so that we can make accurate size design drawings. At the same time, the customer wants us to design the pattern of the paper cup fan, and finally orders 4 tons of paper cup fans and 1 ton of bottom paper.

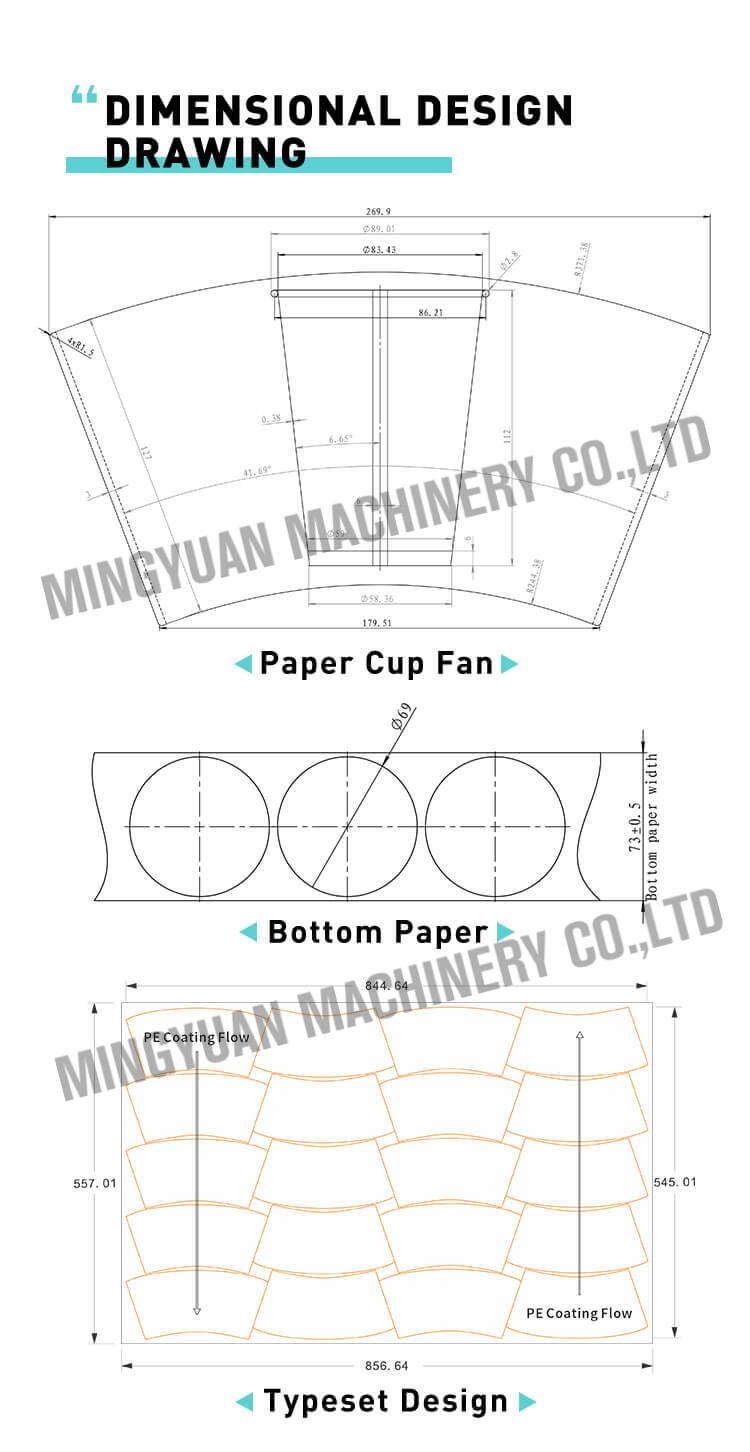

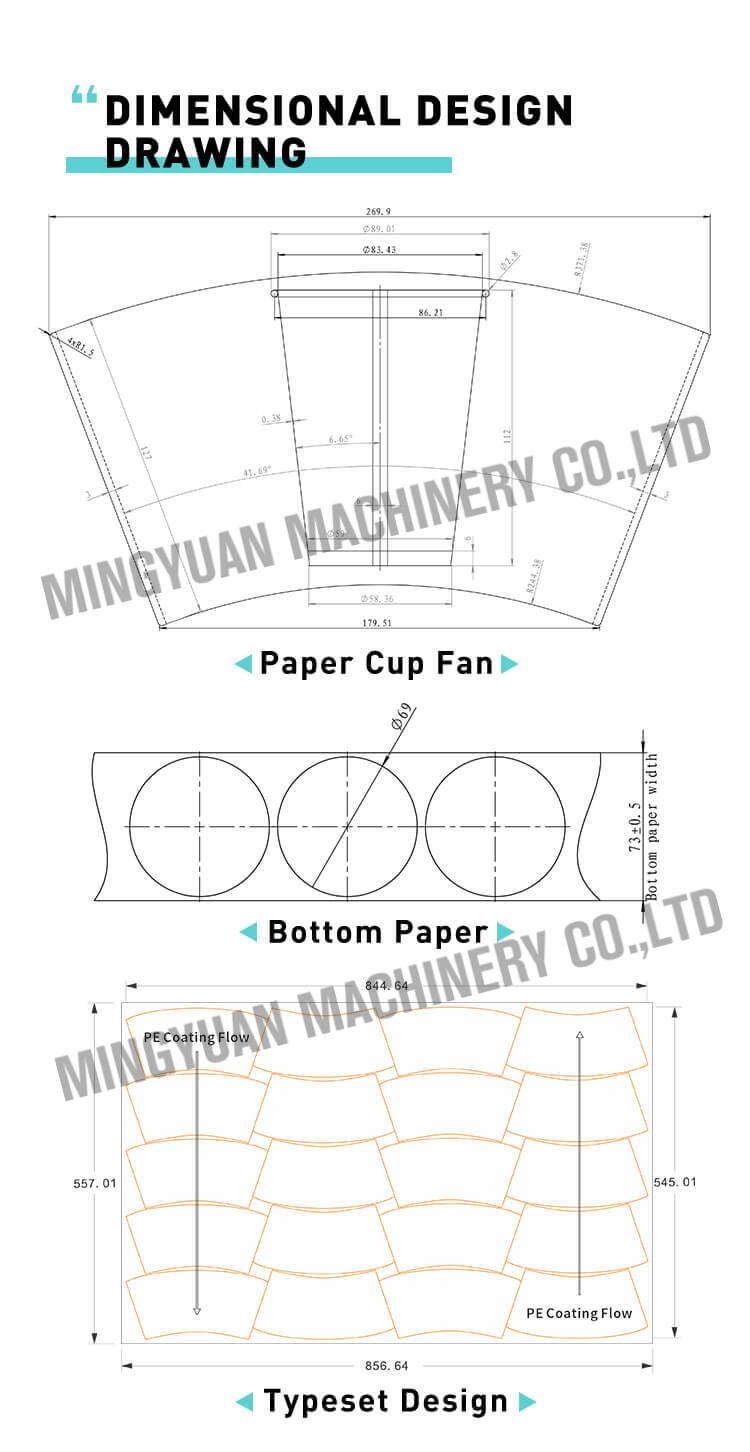

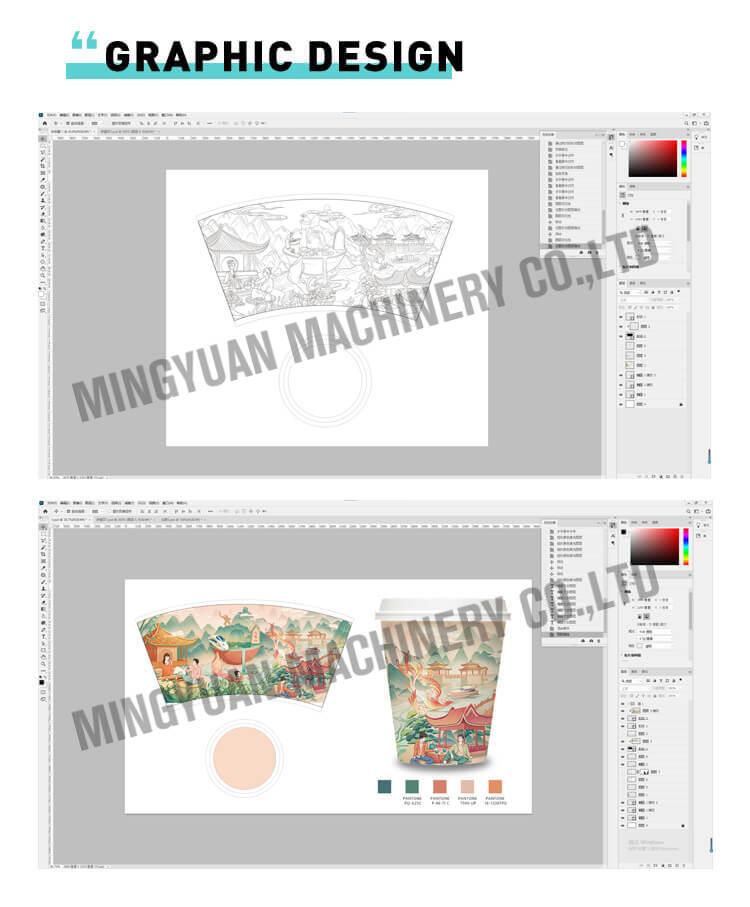

Size design drawing: In this stage, we first make the size design drawing of paper cups and paper cup fans (according to the customer's samples). Secondly, we draw the typeset design drawing (according to the paper cup fan design drawing)

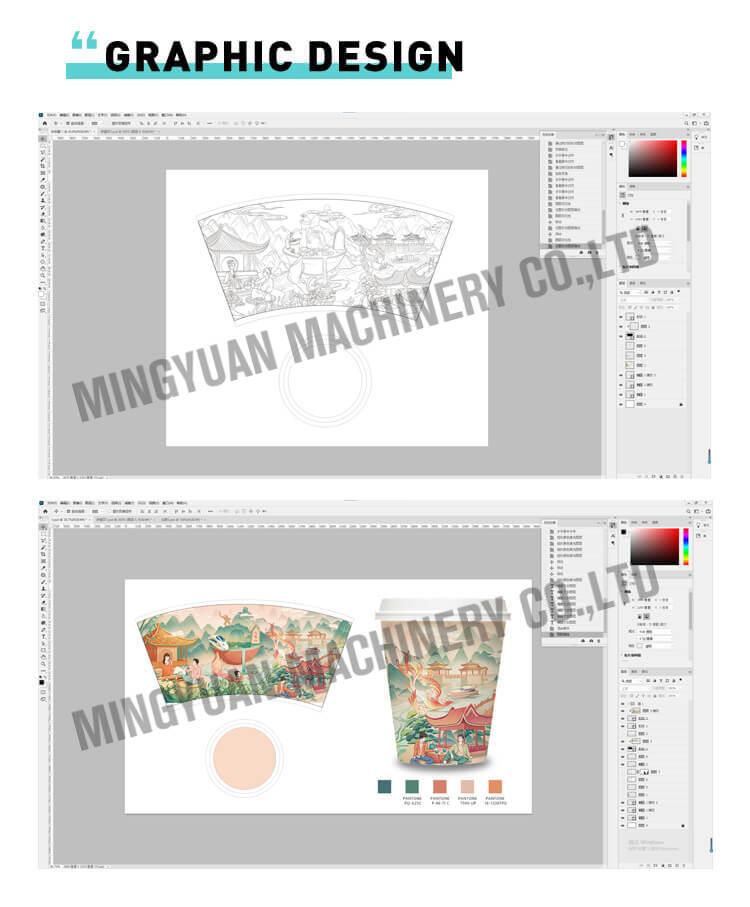

Draft design: We make the draft design of the paper cup fan and the bottom paper according to the requirements provided by the customer. After the draft design is completed, we send the plan to the customer for review. The customer can make revisions and we will make adjustments based on the feedback to ensure that every detail meets the customer's expectations.

Professional coloring: Using advanced design tools, we perform precise coloring for the paper cup fan and the bottom paper. Ensure color accuracy and high quality of printing effects to avoid color differences during production.

Sample production and confirmation: After the design is completed, we will make a small number of paper cup samples or provide electronic sample drawings to customers for final confirmation. This step is an important step to ensure that the design meets customer expectations. Customers can check the samples, and if necessary, we will further adjust the design based on feedback.

Through the above process, we ensure that we provide customers with the most suitable paper cups and paper cup fans, and maintain high standards of quality control in every link, striving to meet customer expectations for every product.

Part 4: Production process and quality inspection after ordering

After the customer places an order, our production process includes several important steps to ensure the high-quality delivery of paper cup machines and paper cups. The following is a detailed description of this process:

1. Paper Cup Machine Production Process

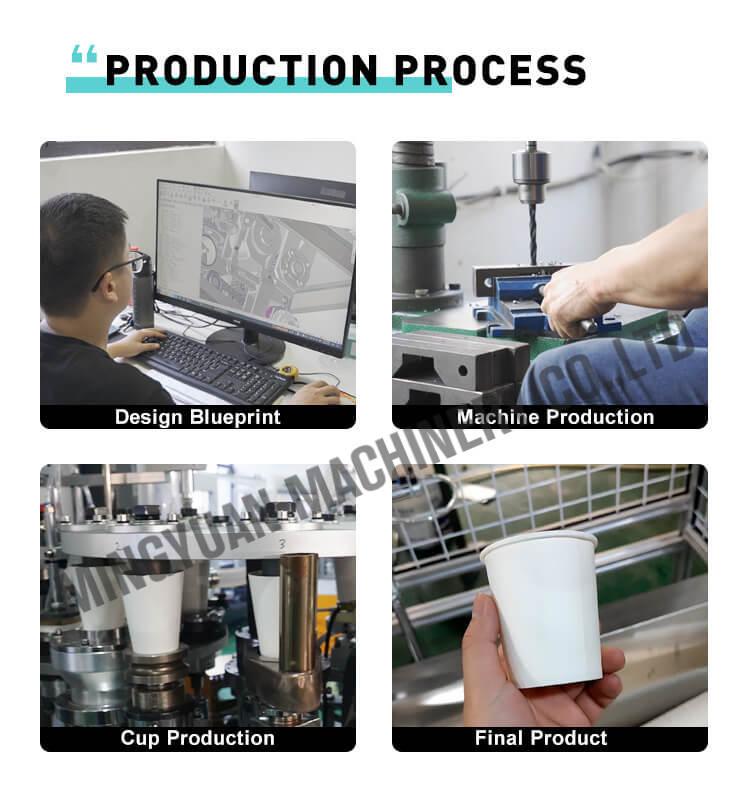

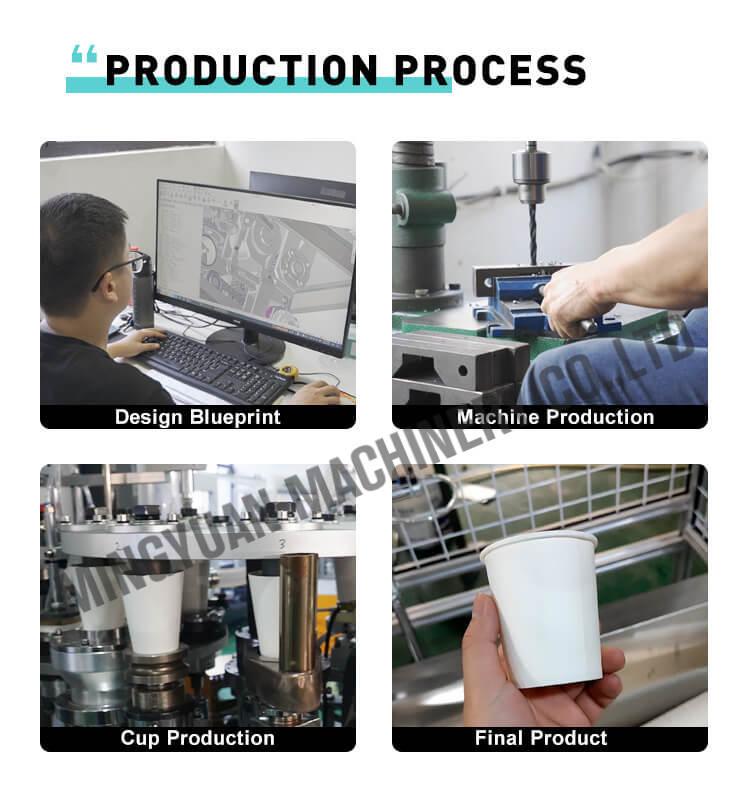

Design Blueprint:According to the specific requirements of the customer, we first make a detailed blueprint and specifications of the paper cup machine. This includes the structural design, functional modules and technical parameters of the equipment. After the design blueprint is confirmed by the customer, we will start the production stage.

Machine Production:After the design blueprint is confirmed, we start to manufacture the paper cup machine. This stage includes assembly, debugging and comprehensive functional testing. We ensure that all parts are processed and assembled according to high standards to ensure the stability and performance of the paper cup machine.

2. Paper Cup Production Process

Produce Paper Cups:After the paper cup machine is produced, we use it for small-scale paper cup production. The purpose of this stage is to test the actual operation effect of the paper cup machine and the quality of the produced paper cups.

3. Quality Inspection and Final Audit

Quality Inspection:We conduct detailed quality inspection on all produced paper cups, including size inspection, sealing test and appearance quality inspection. We use professional testing tools and standards to ensure that every paper cup meets our high quality requirements.

Sample Review and Customer Confirmation:After completing the production and quality inspection of paper cups, we will make samples and send them to customers. Customers can check and confirm the samples to ensure that the final product meets their expectations and needs.

Part 5: Transportation and Delivery

Production completion and delivery:After customer confirmation, we carry out final production and prepare the paper cups and paper cup machines for delivery. We will arrange packaging and logistics to ensure that the products are delivered to customers safely and on time.

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China