The production process of paper cup moulding machine involves various intricate steps that are essential for manufacturing high-quality machines used in the production of paper cups. From designing to assembly, each stage plays a crucial role in ensuring the efficiency and reliability of the final product.

Designing Stage

At the beginning of the production process, the design stage sets the foundation for the paper cup moulding machine. Engineers and designers work together to create detailed blueprints and specifications for the machine. Factors such as size, capacity, speed, and precision are carefully considered during this stage to meet the specific requirements of the customers.

Material Selection

Once the design is finalized, the next step involves selecting the materials for constructing the machine. High-quality materials such as stainless steel, aluminum, and durable plastics are chosen to ensure the longevity and performance of the paper cup moulding machine. The selection of materials is crucial in determining the overall quality and durability of the machine.

Manufacturing Components

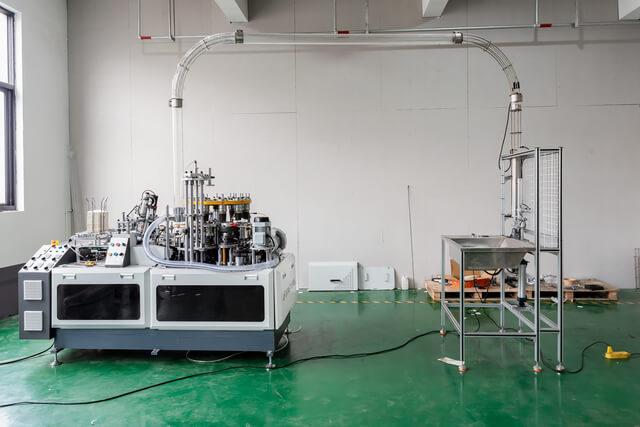

In this stage, the various components of the paper cup moulding machine are manufactured according to the design specifications. Each component, including the moulds, frames, motors, and control systems, is meticulously crafted to precise measurements. Skilled technicians and automated machinery are employed to ensure consistency and accuracy in manufacturing the components.

Assembly Process

Once all the components are manufactured, the assembly process begins. Skilled technicians carefully assemble the machine, following the detailed instructions provided in the design blueprint. The components are fitted together with precision, and the electrical and mechanical systems are integrated to ensure seamless operation of the paper cup moulding machine.

Quality Control

Quality control is a critical stage in the production process of paper cup moulding machines. Each machine undergoes rigorous testing to ensure that it meets the highest standards of quality and performance. Various tests, including stress tests, performance tests, and safety checks, are conducted to identify and rectify any defects or issues before the machine is released to the market.

Final Inspection

Before the paper cup moulding machine is ready for shipment, a final inspection is carried out to verify that all components are functioning correctly and that the machine meets the required specifications. Any last-minute adjustments or refinements are made during this stage to guarantee the optimal performance of the machine once it reaches the customer.

Packaging and Shipment

After passing the final inspection, the paper cup moulding machine is carefully packaged to prevent any damage during transportation. Specialized packaging materials are used to protect the machine from vibrations, impacts, and environmental factors. The machine is then shipped to the customer's location, where it will be installed and put into operation.

Installation and Training

Upon delivery, the paper cup moulding machine is installed at the customer's facility by a team of skilled technicians. They ensure that the machine is set up correctly and provide training to the operators on how to use and maintain the machine effectively. This step is crucial in maximizing the efficiency and longevity of the paper cup moulding machine.

Conclusion

In conclusion, the production process of paper cup moulding machines is a complex and meticulous procedure that involves careful planning, precise execution, and stringent quality control measures. Each stage, from designing to installation, plays a vital role in ensuring the functionality and durability of the final product. By adhering to high standards and attention to detail, manufacturers can deliver reliable and efficient paper cup moulding machines to meet the demands of the market.

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: paperproductwholesaler@gmail.com

Email: paperproductwholesaler@gmail.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China