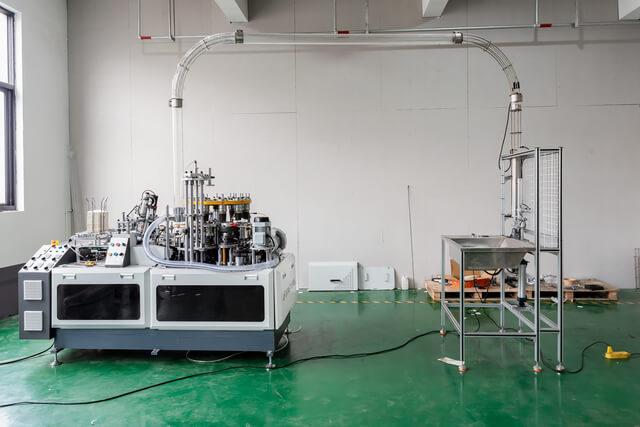

High speed paper cup making machines play a crucial role in the production of disposable paper cups, catering to the growing demand for eco-friendly and convenient packaging solutions. These machines are designed to efficiently manufacture paper cups in large quantities, ensuring high productivity and quality output.

1. Raw Material Preparation

The production process of high speed paper cup making machines begins with raw material preparation. The primary material used is food-grade paperboard, which is coated with a layer of polyethylene to make it waterproof. The paperboard rolls are loaded onto the machine, ready to be transformed into paper cups.

2. Printing and Cutting

Once the paperboard is loaded onto the machine, the printing and cutting process begins. The paperboard is fed through the machine, where the cup design is printed onto the surface. Simultaneously, the paperboard is cut into the required shape and size to form the body of the paper cup.

3. Forming the Cup Body

After the paperboard is printed and cut, the next step involves forming the cup body. The paperboard is shaped into a cylindrical form and sealed using heat or adhesive to create the cup structure. This process is crucial in ensuring the integrity and stability of the paper cup.

4. Bottom Sealing

Once the cup body is formed, the bottom sealing process takes place. A separate piece of paperboard is cut and shaped to create the base of the cup. This base is then attached to the cup body using heat or pressure, securely sealing the bottom of the paper cup.

5. Curling the Rim

After the bottom sealing process, the top edge of the paper cup undergoes curling to create a smooth and rounded rim. This step not only enhances the appearance of the paper cup but also provides additional strength and comfort for the user when drinking from the cup.

6. Quality Inspection

Quality inspection is a critical stage in the production process of high speed paper cup making machines. Automated systems are used to inspect each paper cup for defects, ensuring that only high-quality cups are packaged and shipped to customers. Any cups that do not meet the standards are rejected and recycled.

7. Packaging and Stacking

Once the paper cups pass the quality inspection, they are ready for packaging and stacking. The cups are automatically counted, stacked, and packaged into boxes for transportation. This final stage of the production process ensures that the paper cups are delivered to customers in an organized and efficient manner.

8. Maintenance and Cleaning

Regular maintenance and cleaning of high speed paper cup making machines are essential to ensure smooth operation and longevity. The machines need to be regularly inspected, lubricated, and cleaned to prevent breakdowns and maintain optimal performance. Proper maintenance practices help extend the lifespan of the machines and reduce downtime.

Conclusion

In conclusion, the production process of high speed paper cup making machines involves several key stages, including raw material preparation, printing and cutting, forming the cup body, bottom sealing, rim curling, quality inspection, packaging and stacking, as well as maintenance and cleaning. These machines have revolutionized the paper cup manufacturing industry by enabling efficient and cost-effective production of disposable paper cups. With advancements in technology and automation, high speed paper cup making machines continue to drive innovation and sustainability in the packaging industry.

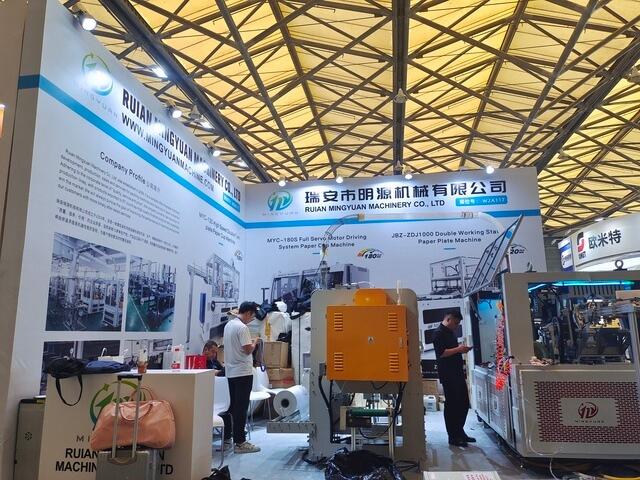

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: paperproductwholesaler@gmail.com

Email: paperproductwholesaler@gmail.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China