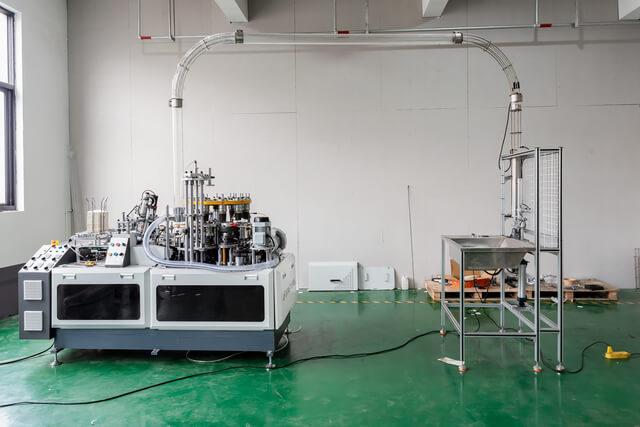

Installing a paper cup high-speed machine is a crucial step for businesses looking to enhance their production efficiency and meet the growing demand for paper cups in the market. This advanced machinery automates the process of manufacturing paper cups, increasing output while maintaining quality standards. In this article, we will explore the installation process of a paper cup high-speed machine in detail, highlighting the key steps and considerations involved.

1. Preparing the Installation Site

Prior to installing the paper cup high-speed machine, it is essential to prepare the installation site. The area should be clean, spacious, and well-ventilated to ensure smooth operations. Clearing out any obstacles and ensuring that the necessary utilities such as electricity and water supply are readily available are crucial steps in preparing the site.

2. Unpacking and Assembling the Machine

Once the installation site is ready, the next step involves unpacking the components of the paper cup high-speed machine and assembling them according to the manufacturer's instructions. Carefully follow the assembly guidelines to ensure that the machine is put together correctly, preventing any issues during operation.

3. Connecting Utilities

After the machine is assembled, the next step is to connect the necessary utilities such as electricity and water supply. It is important to follow safety protocols and guidelines when connecting these utilities to prevent accidents and ensure the efficient functioning of the machine.

4. Testing and Calibration

Once the machine is assembled and the utilities are connected, it is time to test the equipment and calibrate it for optimal performance. Conducting thorough testing procedures will help identify any potential issues or adjustments that need to be made before full-scale production begins.

5. Training Operators

Training operators on how to use the paper cup high-speed machine is crucial for ensuring smooth operations and maximizing productivity. Provide comprehensive training sessions to familiarize operators with the machine's functionalities, maintenance procedures, and troubleshooting techniques.

6. Initial Production Run

After testing, calibration, and operator training are completed, it is time to conduct the initial production run with the paper cup high-speed machine. Monitor the production process closely to identify any teething issues and make necessary adjustments to optimize efficiency and quality.

7. Maintenance and Ongoing Support

Maintaining the paper cup high-speed machine is essential for prolonging its lifespan and ensuring consistent performance. Establish a regular maintenance schedule and provide ongoing support to address any issues that may arise during operation.

8. Monitoring Performance and Optimization

Continuously monitor the performance of the paper cup high-speed machine and gather data to identify areas for optimization. Implement improvements and upgrades as needed to enhance productivity, reduce downtime, and meet changing market demands.

Conclusion

Installing a paper cup high-speed machine involves a series of crucial steps, from site preparation to ongoing maintenance and optimization. By following the outlined process and paying attention to details, businesses can successfully integrate this advanced machinery into their production operations, boosting efficiency and meeting the growing demand for paper cups in the market.

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China